All For Customers, For All Customers

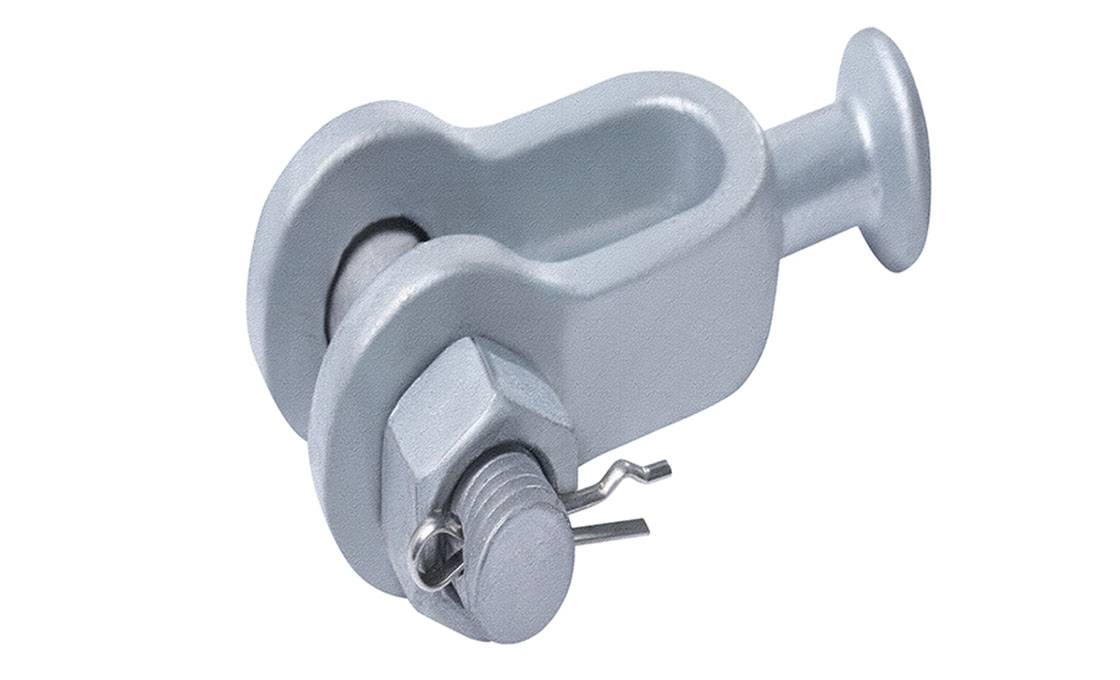

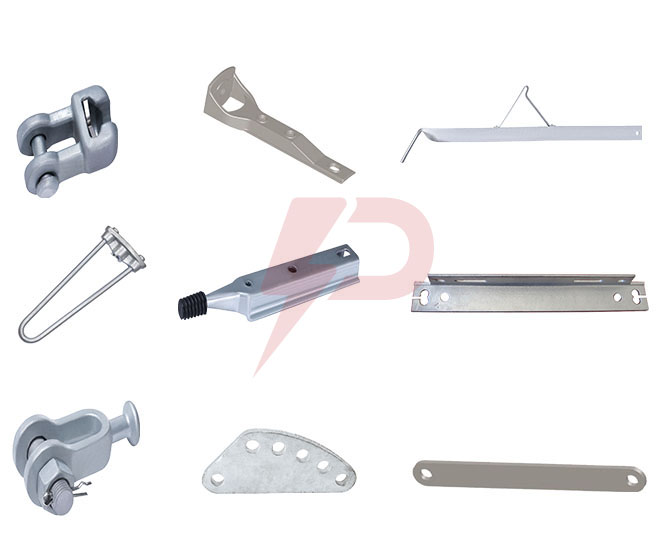

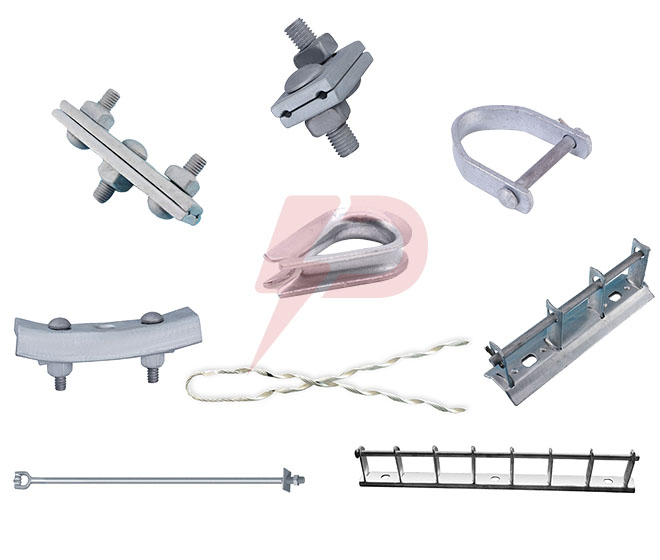

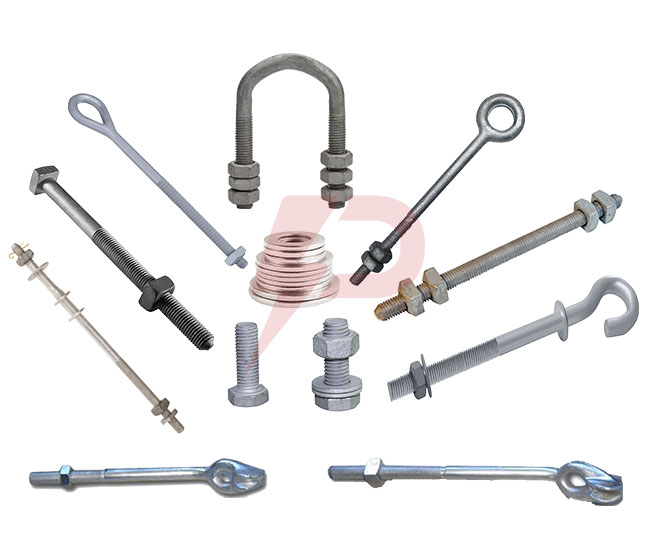

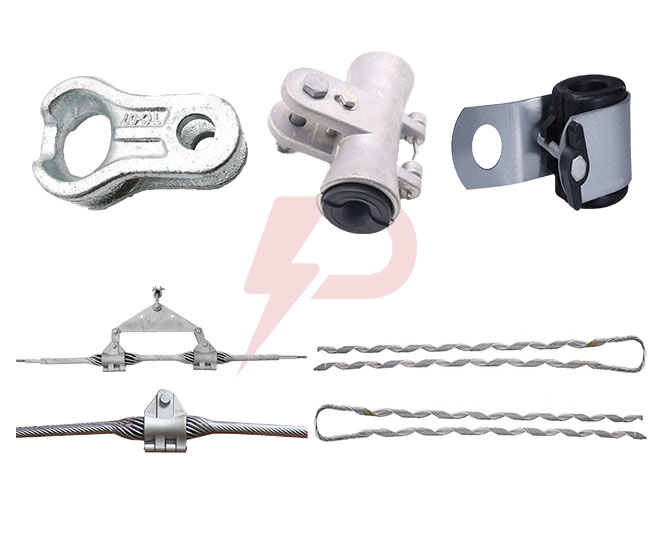

Customized Power Fitting

Why Heavy Customers Trust Us?

Product Category

View details

View details

View details

Our Successful Project All Over the World

Tanzania Electric 33KV MV Networks:

Jordan H.T. Overhead Line Networks:

Kenya Overhead Line Project:

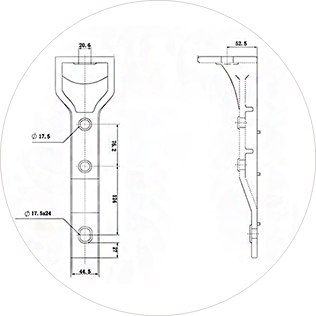

You Provide A Design, We Make It Real

If you have any new design, you can send us a drawing or sample, Our engineer will make it come true.

Based on your idea, we will confirm the final drawing and make new tooling. Tooling cost will refund after 5000pcs order.

More Solutions to Help You Buy the Perfect Electric Power Fitting

FAQ

For the different types of pole line hardware, there are different ways to do the hot-dip galvanization.

For the electrical cross arm, alley arm, the manufacturer does the hot-dip galvanization at a big bow, the liquid temperature was controlled very well. And the consist element was settled according to a certain percent.

For the casting part like socket clevis and pole top bracket, there is a different element consist to do the hot-dip galvanization.

There are a few kinds of hot-dip galvanization testing standard for the overhead line fitting.

For the Asia market, like Malaysia and Indonesia, they test the hot-dip galvanization according to ISO1461.

For South America, they test the hot-dip galvanization according to ASTM123.

The manufacturer usually charges the tooling, if you don’t accept our present power fitting type.

The manufacturer will make new tooling based on your design, and the new tooling belongs to you. The manufacturer just helps you to take care of the tooling in our factory.

If you have paid for it, the manufacturer can also refund you the tooling cost if you ordered a certain quantity.

Yes, of course. It’s a necessary step to confirm the sample before mass production.

If the type of pole line hardware you required is in stock, the customer will only burden the express cost and have the sample for free.

If you need to make new samples according to your drawing, you should charge the sample cost.

Only T/T and L/C are acceptable, OA is not.

If the pole line hardware you required is in stock, the goods will be shipped immediately after you pay.

If there is no stock for your required, 20 days are needed to make 1*20 containers and confirm further whether it is needed to make new tooling for it.