Yoke Plate

Yoke plate is a type of string hardware used for coupling the electrical clevis and the insulators or the socket tongue on the transmission line. During the yoke plate installation process, the insulators that are connected to the cross arm will be on one side and the conductor termination is on the other side.

Yoke plates can be made of carbon steel, ductile iron, forged steel and aluminum alloy. When it comes to the construction, a yoke plate is usually made high-grade steel carbon. This material is relatively thick enough to give it enough strength. The tensile strength of the material shields it from breaking of undergoing structural damage. The powerline fitting is designed to have a high rated breaking strength(RBS).

Still, in terms of the construction, the material for the yoke plate is hot dip galvanized. This coating protects against corrosion and rust. Water and chemicals that come into direct contact with the yoke plate won’t cause any degradation. The surface of the yoke plate is smooth and does not have lumps.

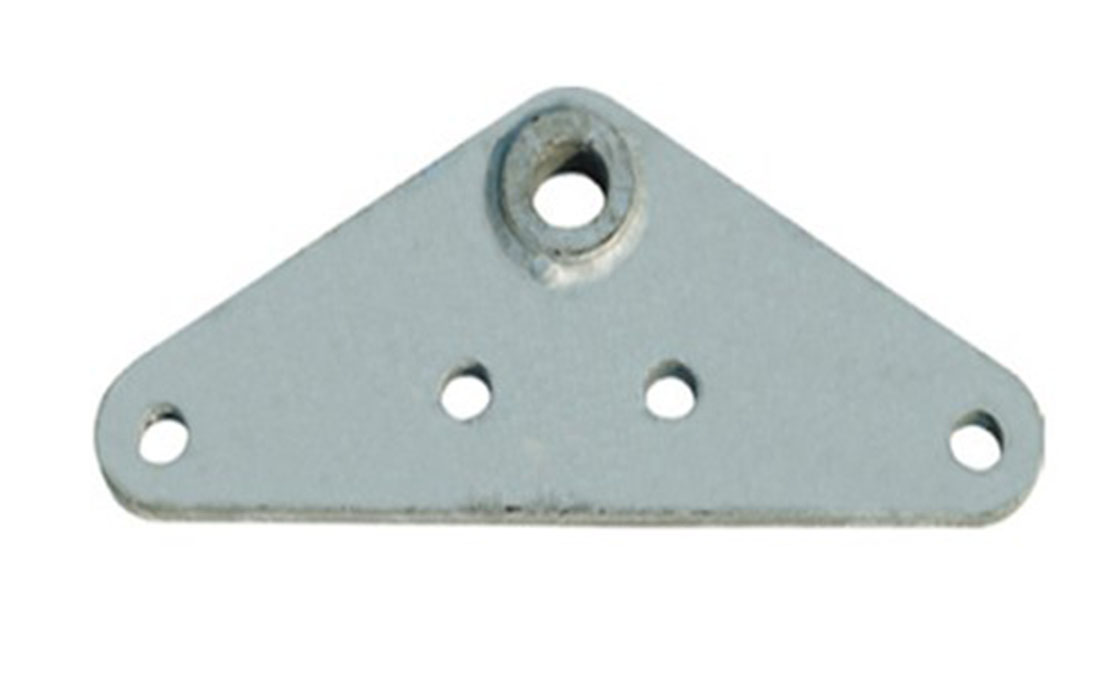

For the design, the most common shape of the yoke plate is the triangular yoke plate. This shape is considered universal as it can easily fit into a wide range of applications.

However, there are other shapes for this overhead line accessory. You can find a rectangular yoke plate and even an irregularly-shaped yoke plate. So, when buying a yoke plate, you should specify the design or shape that you want. Of course, the choice of the shape will depend on your area of application.

Yoke plates have grooves or holes through which connections are made. The diameters of these holes tend to vary. This means that you need to be more specific with the size of the holes that you want.

In case you would like to get more information about the yoke plate, just contact Powertelcom and we will be glad to serve you.

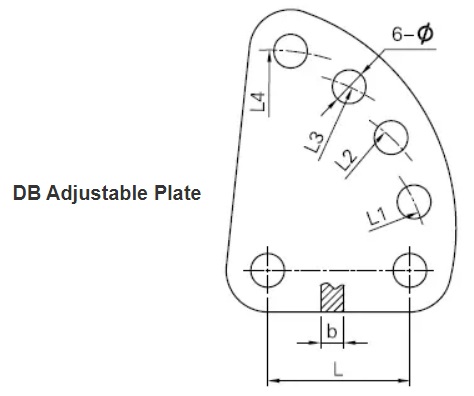

| Cat.No. | Dimensions(mm) | Failure Load(kn) | Weight(kg) | ||||||

| Ø | L | L1 | L2 | L3 | L4 | b | |||

| DB-7 | 18 | 70 | 95 | 120 | 145 | 170 | 16 | 70 | 1.7 |

| DB-10 | 20 | 80 | 110 | 140 | 170 | 200 | 16 | 100 | 2.7 |

| DB-12 | 24 | 100 | 135 | 170 | 205 | 240 | 16 | 120 | 3.2 |

| DB-16 | 26 | 110 | 125 | 140 | 155 | 170 | 18 | 160 | 4.1 |

| DB-20 | 30 | 120 | 135 | 150 | 165 | 180 | 26 | 200 | 7.4 |

| DB-25 | 33 | 120 | 140 | 160 | 180 | 200 | 30 | 250 | 11.5 |

| DB-30 | 39 | 120 | 140 | 160 | 180 | 200 | 32 | 300 | 12.5 |

| DB-60 | 51 | 135 | 160 | 185 | 210 | 235 | 42 | 600 | 21.6 |

| DB-5024 | 45 | 140 | 165 | 190 | 215 | 240 | 38 | 500 | 18.5 |

| DB-5032 | 45 | 140 | 185 | 230 | 275 | 320 | 38 | 500 | 14.4 |

| DB-0770-170 | 18 | 70 | 95 | 120 | 145 | 170 | 16 | 70 | 1.7 |

| DB-1080-200 | 20 | 80 | 110 | 140 | 170 | 200 | 16 | 100 | 2.7 |

| DB-12100-240 | 24 | 100 | 135 | 170 | 205 | 240 | 16 | 120 | 3.2 |

| DB-16110-170 | 26 | 110 | 125 | 140 | 155 | 170 | 18 | 160 | 4.1 |

| DB-21120-180 | 26 | 120 | 135 | 150 | 165 | 180 | 20 | 210 | 6.2 |

| DB-32120-200 | 33 | 120 | 140 | 160 | 180 | 200 | 28 | 320 | 9.2 |

| DB-42140-320 | 39 | 140 | 185 | 230 | 275 | 320 | 32 | 420 | 16.5 |

| DB-64150-310 | 45 | 150 | 190 | 230 | 270 | 310 | 36 | 640 | 27.5 |

| DB-84140-260 | 51 | 140 | 170 | 200 | 230 | 1260 | 38 | 840 | 24.8 |

| DB-110170-320 | 55 | 170 | 200 | 240 | 280 | 32 | 40 | 1100 | 34.2 |

| DB-12810-320 | 64 | 170 | 200 | 240 | 280 | 320 | 45 | 1280 | 50 |

Yoke Plate for Transmission Line Complete Buying Guide

On a typical transmission line, you are likely to see sagging conductors. They appear to be freely suspended or floating on the air supported by strings. Hence sagging and stringing. There are various reasons for this.

Different powerline accessories are used for stringing and sagging the conductors and one of them is the yoke plate. If you are dealing with a powerline project, a yoke plate should always be among the insulator fittings that you should buy.

If you are planning to buy yoke plates, this is the right guide for you. We are going to give you valuable insights that you should know about this insulator fitting for the overhead power line.

What is a Yoke Plate for transmission line?

A yoke plate is among the most common insulator fittings that are used on overhead transmission lines. It is a string hardware that is used for stringing different components of an overhead power line.

A yoke plate is stringed to the insulators on one side and the other side is stringed to the conductor terminal point.

Other components of an overhead pole line such as socket tongue and clevis are also attached to the yoke plate.

The connection between the yoke plate and the associated components must be fault-proof to guarantee structural and electrical integrity of the transmission line.

Also, the yoke plates themselves must be of high quality to ensure that they execute their jobs without breaking or getting damaged.

Yoke Plate Assembly

The yoke plate assembly defines parts and components that make up a yoke plate. The assembly will determine the overall functionality and efficiency of the yoke plate transmission line.

A yoke plate assembly comprises a flat surface and holes that are positioned at different b points of the plate.

The plate can take different shapes depending on how you would like to install on the power transmission.

Yoke plate assembly shall meet your local standards or the following industrial requirements:

ASTM A153 – Standardized Specification for Zinc Coating (Hot-Dip) on Iron and Steel Hardware

ASTM A47 – Standard Specification for Ferritic Malleable Iron Castings

ASTM A668 – Standard Specification for Steel Forgings, Carbon and Alloy, for General Industrial Use

Federal Specification RR-C-271D – Chains and Attachments Carbon and Alloy Steel

How is a Yoke Plate Manufactured?

Although it is a simple pole line accessory, intricate procedures are followed when manufacturing yoke plates.

A yoke plate electric insulator fitting is formed through the process of oxy arc cutting. It is through this process that the shape and design of the plate are formed.

The manufacturer must cut the plate to precision so that there are no rough edges or lumps on the final product.

Once the shape has been formed, the next process entails creating holes on the yoke plate. Here a 140ton punching machine is used to create holes that must have precise dimensions.

The surface of the yoke plate is then hot dip galvanized so that it is free from rust and corrosion.

The plate is tested against all the constraints to ensure that it is 100% fit for use. From there, it is supplied to the clients for installation on the transmission line.

Reputable yoke plate manufacturers ensure that all the due procedures are followed before the pole line fitting is presented to the customers.

What are Yoke Plates Made of?

Yoke plates can be made of carbon steel, ductile iron, forged steel and aluminum alloy. The most common used yoke plates in the market are made of carbon steel.

This material is chosen because of the physical strength that it exhibits. The carbon plate is rated among the toughest for steel hence ideal for making such pole line fittings.

The tensile strength of carbon steel ensures that it can withstand loads of both the conductor that they are suspended from.

Another advantage of carbon steel is high resistance to rust, corrosion, and abrasion. Since the clevis plate is exposed to elements of weather such as water and chemicals, the extra protection makes the pole line fitting durable.

The hot dip galvanization process that the plate is subjected to gives it an extra layer of protection.

Types of Yoke Plates

Before buying yoke plates, it is vital to be aware of the fact that they are not all the same. They come in different designs and styles, and they are applied to different numbers of conductors in many installations. Each type is suited to function well on specific power lines.

According to the number of conductors they are connected to, there are 4 types of Yoke Plates: 1 conductor yoke plates, 2 conductor Yoke Plates, 3 conductor yoke plates, and 4 conductor yoke plates.

According to their shapes and designs, there are 6 common types of Yoke Plates:

Triangular Yoke Plates

Also named Delta Yoke Plates, they can be used in suspension applications with a single string of insulators, or used in deadend applications with two strings of insulators and one deadend clamp.

Rectangular yoke plate

They deadend a two conductor bundle with a double string of insulators.

Trapezoidal yoke plate

V-String yoke plate

With a V string of insulators, the V sharp yoke plates can bundle two conductors, while the T sharp yoke plates can bundle three.

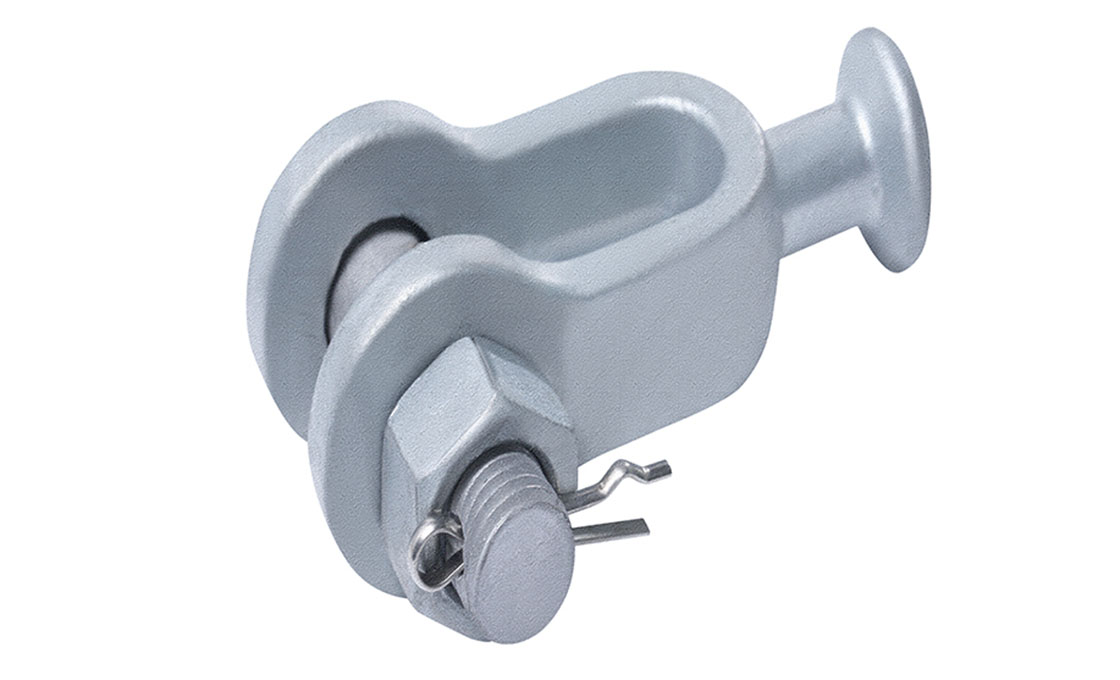

Tension Adjustable yoke plate

Tension Adjustable yoke plate which is connected to deadend hardware, can change the assembly attachment point and maintain desired line tension.

Crescent yoke plate

These yoke plates are used to connect a two conductor bundle with various insulators, such as single, v-string, or single string insulators, and keep the proper running angle of the cable.

Jumper Yoke Plate

These jumper yokes are used to connect different numbers of conductors with a single string of insulators on a deadend tower.

The working mechanism of all the three types of yoke plates is the same. They only differ on the positioning of the insulator s and conductors that are strung to the plate.

So, which type of yoke plate should I choose for my project? You may ask.

The choice of the clevis plate type will depend on the specifications of the pole line and what you intend to achieve.

Your project engineer will also give you relevant advice regarding the type of yoke plate that you should buy.

Yoke Plate Specifications

In addition to the types, you should also be fully aware of the specifications of each yoke plate that you are buying.

Even though you may get the right type of yoke plate, its specifications may not be suitable for your application. The specifications give out full details of the products that you are about to get from the manufacturer.

Key specifications of a yoke plate include length, size of the holes, number of the holes, the weight of the plate, and the width.

Once you confirm the details and decide what will fit the scope of your application, you can proceed to buy the yoke plate in China.

Yoke Plate Manufacturer China-PowerTelcom

Powertelcom offers a variety of yoke plates that will fulfill the needs of your power utility. From us, you will be able to get dead-end yoke plates, V-String yoke plates, 3 conductor jumper yoke plates, and triangular yoke plates.

Our manufacturing standards are impeccable and we follow the IEEE guidelines for manufacturing electrical accessories. You will not have any doubts regarding the quality of our yoke plates.

We are an experienced yoke plate manufacturer in China. The many years that we have been in the business of manufacturing power line utilities have equipped us with the knowledge that will be critical in developing the best clevis yoke.

So, when you are looking for a yoke plate manufacturer in China-Choose Powertelcom.

Frequently asked questions (FAQ)

What is a Yoke Plate?

A yoke plate is among the most common insulator fittings that are used in overhead transmission lines. It is a string hardware that is used for stringing different components of an overhead power line.

What is the yoke plate made of?

The Yoke plate is designed to have a high-rated breaking strength (RBS). Yoke plates can be made of carbon steel, ductile iron, forged steel, and aluminum alloy. The most commonly used yoke plates in the market are made of carbon steel.

Types of Yoke Plates

According to the number of conductors they are connected to, there are single conductor yoke plates, double conductor Yoke Plates, and multi-conductor yoke plates.

According to the sharp, there are triangular yoke plates, rectangle yoke plates, V-string yoke plates, adjustable yoke plates, and other irregularly-shaped yoke plates.