Forged Eye Bolt

A forged eye bolt is an overhead power line accessory that is used for connecting dead end insulator in an overhead line. The power line fitting is widely used on wooden poles whereby it can connect the overhead line or even dead end insulator.

It can also be referred to as the drop forged eye bolt or just forged eyebolt.

Forged eye bolts come in two main designs. These are the oval eye bolts and the round eye bolts. The forged oval eye bolt has a thimble. When you connect the eye bolt to the clevis or a dead end insulator, this thimble will remain locked.

Forged eye bolts are usually assembled with square and hex nuts. The nut is then fastened on the eye bolt once it has gone across the wooden pole.

Our forged eye bolts are made of galvanized steel and are not welded at any point. This means that you can be sure about the strength of this electric power line accessory.

The galvanization is there to protect against corrosion. Water and other chemicals won’t have negative effects on these power line fittings.

To buy forged eye bolts, simply contact us as we are a reputable forged eye bolt manufacturer in China.

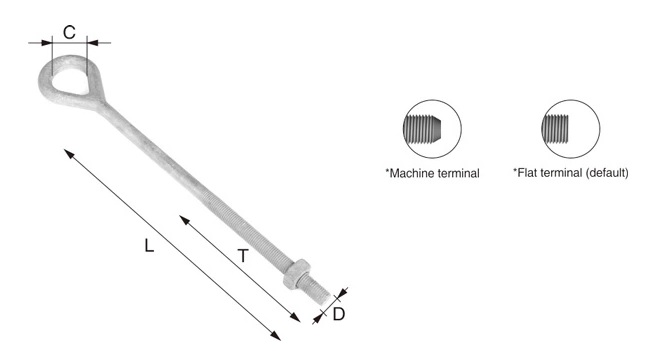

| Type | Dimensions in inches and millimeters | |||

| C | D | L | T | |

| OEB01 | 1 1/2″(38) | 5/8″(16) | 6″(150) | 4″(100) |

| OEB02 | 1 1/2″(38) | 5/8″(16) | 8″(200) | 4″(100) |

| OEB03 | 1 1/2″(38) | 5/8″(16) | 9″(230) | 4″(100) |

| OEB04 | 1 1/2″(38) | 5/8″(16) | 10″(250) | 6″(150) |

| OEB05 | 1 1/2″(38) | 5/8″(16) | 12″(300) | 6″(150) |

| OEB06 | 1 1/2″(38) | 5/8″(16) | 14″(350) | 6″(150) |

| OEB07 | 1 1/2″(38) | 5/8″(16) | 16″(400) | 6″(150) |

| OEB08 | 1 1/2″(38) | 5/8″(16) | 18″(450) | 6″(150) |

| OEB09 | 1 1/2″(38) | 5/8″(16) | 20″(500) | 6″(150) |

| OEB10 | 1 1/2″(38) | 5/8″(16) | 22″(550) | 6″(150) |

| OEB11 | 1 1/2″(38) | 5/8″(16) | 24″(600) | 6″(150) |

| OEB12 | 1 1/2″(38) | 5/8″(16) | 6″(150) | 4″(100) |

| OEB13 | 1 1/2″(38) | 3/4″(20) | 8″(200) | 4″(100) |

| OEB14 | 1 1/2″(38) | 3/4″(20) | 9″(230) | 4″(100) |

| OEB15 | 1 1/2″(38) | 3/4″(20) | 10″(250) | 6″(150) |

| OEB16 | 1 1/2″(38) | 3/4″(20) | 12″(300) | 6″(150) |

| OEB17 | 1 1/2″(38) | 3/4″(20) | 14″(350) | 6″(150) |

| OEB18 | 1 1/2″(38) | 3/4″(20) | 16″(400) | 6″(150) |

| OEB19 | 1 1/2″(38) | 3/4″(20) | 18″(450) | 6″(150) |

| OEB20 | 1 1/2″(38) | 3/4″(20) | 20″(500) | 6″(150) |

| OEB21 | 1 1/2″(38) | 3/4″(20) | 22″(550) | 6″(150) |

| OEB22 | 1 1/2″(38) | 3/4″(20) | 24″(600) | 6″(150) |

Eye Bolt- The Complete Guide

Eye bolt is a type of steel fasteners that widely used in numerous industrial applications for lifting, rigging, anchoring, pushing, or pulling.

There are various types and materials of eye bolts for different applications, so it is very important to understand and choose the right product.

What is an eye bolt?

An eye bolt is a type of mechanical fastener having a threaded shaft and a ring. It is used for attaching an eye to the structure. This way, any rope, shackles, or cable can be secured to the bolt. The lifting eye is created to help the crane attach to the machinery. This is why lifting eyes for special purposes come to use for a safe working load.

An eye bolt is a type of mechanical fastener having a threaded shaft and a ring. It is used for attaching an eye to the structure. This way, any rope, shackles, or cable can be secured to the bolt. The lifting eye is created to help the crane attach to the machinery. This is why lifting eyes for special purposes come to use for a safe working load.

Low Strength Eye bolts

Low strength eye bolts are created from a bar length having a diameter of a thread (nominal). The unthreaded portion of this bar is where the ring originates. The low strength eye bolts can easily carry the axial loads. However, these types should not be utilized for off axis loads. The opening end can be welded which can cause it to break.

High Strength Eye Bolts

Eye bolts of high strength have forged rings including a shoulder (substantiated). With the help of a shoulder, much of the off-axis load is supported. This is significantly important in the application where multiple eyes for lifting are attached to slings having multiple legs. Therefore, high strength eye bolts endure more weight than low strength eye bolts and hence are used in lifting applications.

For purposes like lifting machinery, the eye bolt has the chances to get screwed directly in the allocated structure’s hole. In this regard, a fully threaded eye bolt is needed that has threads till the shoulder. If a hole is utilized for the insertion of the eye bolt, and nut is used to fasten it, a shank can be of great help. The shank is the unthreaded region of the shaft that is underneath the shoulder. It gives a better load transfer on the hole surface. This makes it resilient to fracture in case of overloading.

Types of Eye bolt used in Power System

Anchor eye bolts

These are eye bolts that come with an anchor bolt so that fastening into masonry objects is made easy.

A double arming bolt is another simple but vital overhead powerline accessory that you will need. It is mainly used for providing support during the cross arm construction process.

A bar length is utilized in making a pigtail. That is why they are similar to the low strength eye bolts. However, the head is helix-shaped. This way, it does not bend and can revolve up to a full degree. This enables a rope to be fully threaded through using screws to a structure.

Ring eye bolts

A captive ring is used in this type of eye bolt which passes through the head eye. This makes two chained links. This helps the dissemination of the force from the eye bolts.

Roller bolt

These bolts are used for guiding a cable or a rope for smooth passing without any undue frictional force. The head is basically an assemblage having four rollers. These are used to retain the rope while it passes through the bolt.

Screw eye bolts

Also known as eye screws, these are similar to a conventional eye bolt. However, a wood screw replaces a machine screw. The eye is attached with the help of this screw to an object. Small versions of this are used for hanging picture frames and other tiny objects.

This is a pole line accessory that is designed to connect or fasten the U channel or steel cross arm to the pole.

Squarehead machine bolt can be used on an overhead transmission line and even a communication line.

Thimble Eye Bolt is used for connecting dead end guy grip to the pole. It can also be used for attaching the guy wires to the concrete line.

Eye bolt Materials

Eye bolts are composed of a variety of materials – the most probable are alloy steel, stainless steel, and carbon.

The stainless steel eye bolts are resistant to rust. This is made possible because of the core material chromium, iron, manganese, nickel, molybdenum, silicon, and some quantity of carbon as well.

Due to this steel eye bolts have more endurance in marine applications. In addition, the fine appearance of the structure is best appropriate for architectural applications and details. Because of the general lack of flaking and peeling, it is also best used in food and pharmaceutical industries.

For cold temperature applications, alloy steel eye bolts are ideal. Lifting structures in temperature below the freezing point of ice must be finished through utilizing an alloy steel eye bolt. The alloy steel has specific metallurgical properties that enable the maintenance of a cold environment and structural integrity.

Galvanized steel eye bolts are developed through molten zinc passed through the standard carbon through hot dipping process that results in an extra layering protecting against the corrosion. Due to this reason, the galvanized eye bolts are perfect for all applications outdoors as they are better resistant to corroding elements. And the price of the steel eye bolts galvanized are much cheaper than the stainless steel ones, so they are widely used in the power system.

Eye Bolts Marking

Eye bolts play a crucial role in workplace safety chain overall. Carefully observing and analysing the specifications of the bolt is important in this regard. Shank diameter is stamped or forged on the ring. This gives the overall size of the bolt. Other specifications and markings include:

Forge code marking for enabling the traceability of the eye bolt to the raw material

- Inner eye diameter

- Exterior eye diameter

- Overall weight and overall length

- Rated Capacity of the eye bolt is actually the capacity of the eye bolt to lift the load when the load is shifted to the shank of the eye bolt

- Angular lifting

As mentioned before, there are different types and sizes of eye bolts available in the market. The actual reason behind is to get different loads safely that are going to be lifted.

Importance of Rated Capacity

As mentioned before, the rated working load, or the rated capacity, is the safe load of the eye bolt for lifting objects. The higher the rated capacity of the eye bolt, the better is the functionality of the eye bolt in that sense.

A standardized lift that is applied via the eye bolt shank is in the condition when the load is put either in two positions. These include vertical and perpendicular positions. The zero degree list is the type of the list used in this regard.

When the lifting starts at some other angle, the rated workload of the eye bolt gets decreased. The more elevated the angle, the lesser is the rated capacity.

Applications of the eye bolt

A lot of varieties of eye bolts that can bear weight are used in the industry. These include eye bolts with more tensile strength and weight capacity. These are used for different functions including creating tension and lifting things.

In commercial settings, professionals also use specific types of eye bolts. They use it to lift weights through a specific angle. These include the eye bolts that come under the machine screw threaded type.

In harsh weather conditions, professionals use welded and stainless steel eye bolts. They are functional for heavy duty purposes. They can utilize it in a humid climate and outdoors.

However, if the weather condition or working condition is different, professionals can use galvanized eye bolts. These are resistant to harsh conditions so there is a better capacity to work for a lot of purposes in the field.

A lot of different types of eye bolts that we mentioned have their own uses, advantages, and features. So, it is important that we select the right type of eye bolt so we can finish our job in the best manner. The stainless steel eye bolt tends to last longer in outdoor environments and is more reliable than other bolts. Especially, professionals use this type of eye bolt in places that are close to the sea where the air is salty.

Now as we have discussed what are the basic types and functions of eye bolts, let’s see the manufacturing process.

The manufacturing process of eye bolt components

Before seeing the process in detail, let us see the summary of the manufacturing process of the eye bolt:

- Wire: the wire is straightened and uncoiled. It is cut to the length

- Cold forging: the steel gets moulded into the right dimension at standard temperature

- Bolt head: the bolt head forms through the steel that is forced into different dyes. They subject to high pressure.

- Thread formation: threads are formed through cutting and rolling

- Heat treating: extreme temperature is present that hardens the steel

- Surface treatment: depending on the application, zinc plating increases resistance to corrosion

Packing and stocking: this process takes place after quality control for getting sure about the consistency and uniformity. After this process, the suppliers pack the final products that proceed for shipping.

Cold forging

The process starts with large steel wire rods. They are cut to length and the grade of the steel is according to the set standard in the industry. It follows the rules of the ISO 898 clause. The professionals use cold forging for the wire using a special tool. This process gives it the right shape. It is where the steel undergoes moulding. As it goes through a series of dyes, high pressure is exerted on the wire.

The process of tolling is not simple. There are at least two hundred different parts that have a high tolerance to a hundredth of a millimetre. When the process undergoes completion, the cold forging is able to quickly produce the products. The products get finished in big volumes and all of them have uniformity. Cold forging starts with large steel wire rods, which are uncoiled and cut to length. The grade of steel is standardized across the industry, according to the requirements of ISO 898‑1.

Turning and drilling

The bolt designs that are more complex often need multiple processes. For instance, there is an additional process called turning. Another process involves drilling. In the turning process, the bolt is undergone spinning at a high speed. The steel is cut away for getting the required dimension and look of the eye bolt. The other process, drilling, makes holes through the product. On requirement, some bolts might need to have washers that attach at the stage of the process.

Heat treatment

Heat treatment is a standardized procedure that requires bolts. It involves the exposure of the bolt to high temperatures that hardens the steel. Before the heat treatment, the process of threading is applied using cutting or rolling. This takes place when the steel is still soft. It is a similar process to cold forging and includes a die for shaping and moulding the material into the threads. After the process, the cutting process takes place through the removal of steel.

As heat treatment changes the property of the material which makes the steel hard, it is an easy method. This way, the process of threading becomes convenient and cost effective. There will be an improvement in the fatigue performance on the application of the heat treatment to the thread.

Straightening

Some eye bolts might also need a process of straightening. It is better for eye bolts that have more length than their total diameter. The heating process alone might change the bolt to its original shape.

Surface treatment

The surface treatment is dependent on the application of the bolt and the client’s needs. The main point is resistance to corrosion. So the eye bolt is dipped under the galvanizing solution to make a coating on the bolt. It saves the product from harsh conditions. Professionals use a solution having zinc that is then subjected to electric current for this process. The zinc forms a layer. After the process, the product is checked for quality control after which it is packed and supplied.

Final word

The eye bolt is a highly important part of construction and fixation in the engineering as well as the construction wing. There are different types of eye bolts that go under specific processes to make them functional and durable for working for a lot of purposes some of which are explained in the article.

As heat treatment changes the property of the material which makes the steel hard, it is an easy method. This way, the process of threading becomes convenient and cost effective. There will be an improvement in the fatigue performance on the application of the heat treatment to the thread.

Some eye bolts might also need a process of straightening. It is better for eye bolts that have more length than their total diameter. The heating process alone might change the bolt to its original shape.

The surface treatment is dependent on the application of the bolt and the client’s needs. The main point is the resistance to corrosion. So the eye bolt is dipped under the galvanizing solution to make a coating on the bolt. It saves the product from the harsh condition. Professionals use a solution having zinc that is then subjected to electric current for this process. The zinc forms a layer. After the process, the product is checked for quality control after which it is packed and supplied.