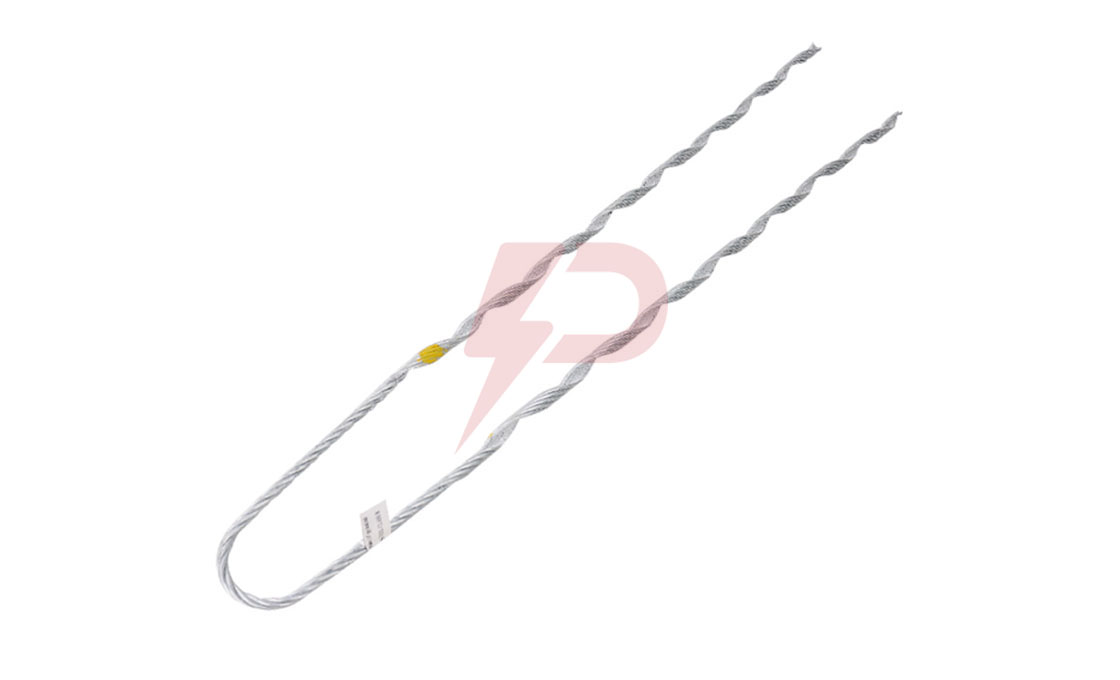

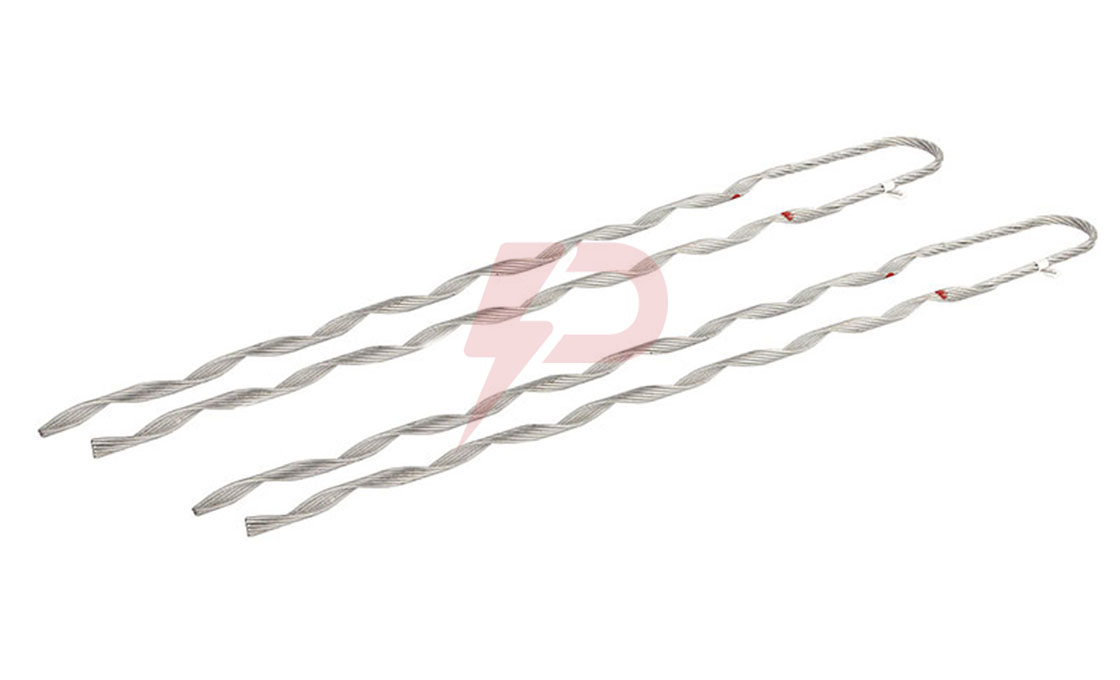

Big Grip Dead End

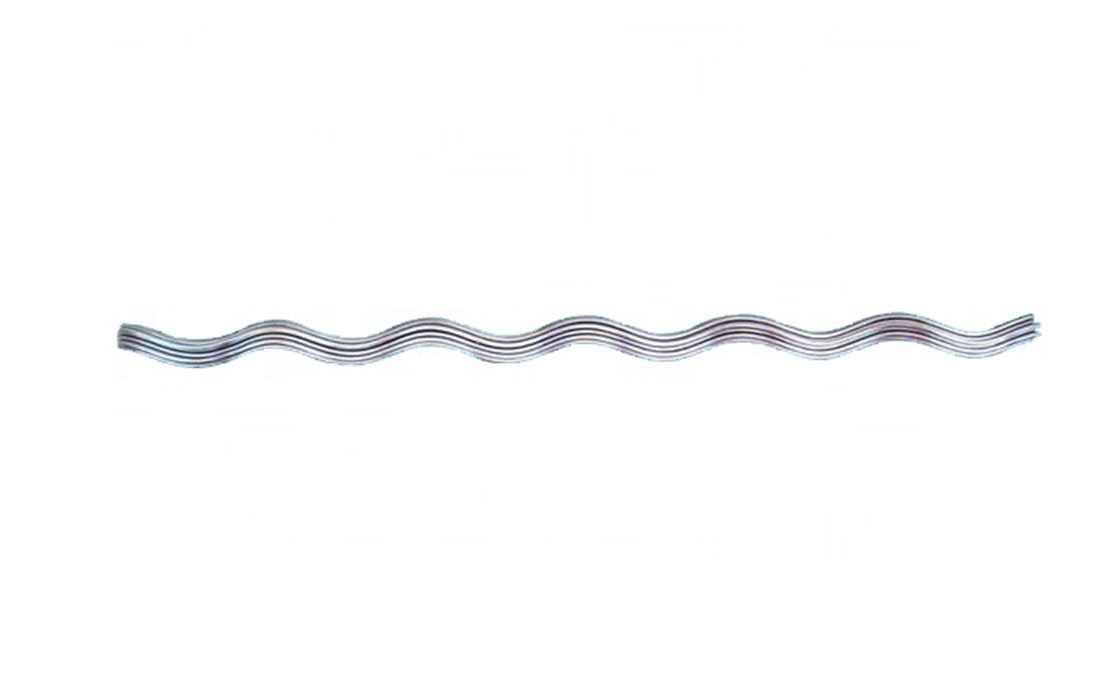

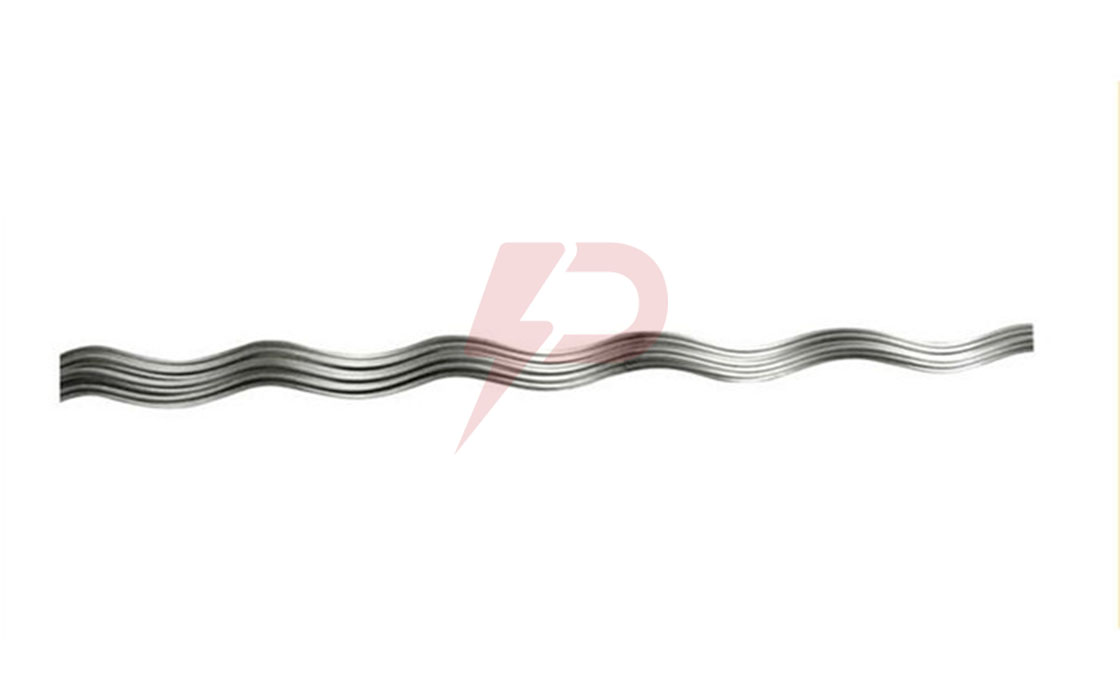

Big grip dead end for the transmission line is an accessory that grips the strands of conductor cable to prevent it from moving or shake and is used for power transmission lines of big capacity and big voltage.

Big grip big dead end can work in harsh field conditions without any problems, which immensely improve the quality of the transmission system.

Big grip big dead end has excellent insulation ability, good anti-shock performance, and a long life span.

Big grip big dead end is made of high-quality aluminum alloy, which can be used in harsh field conditions, big grip big dead end has excellent insulating performance and strong anti-shock ability.

Powertelcom is a professional formed wire manufacturer in China, we can design and supply you with types of preformed line products, contact us now.

Application: big grip big dead end applied for a big power transmission line of big capacity and big voltage.

Big grip big dead end can work in harsh field conditions without any problem, which significantly improves the quality of the transmission system.

Specification:

- Connecting type: dead end with lock pin and without lock pin and big grip big dead end with big lock pin and big lock pin

- Material: Aluminum alloy, and galvanized steel, etc.

- Length: It comes in different lengths depending on the specific application areas.

Frequently Asked Questions (FAQs)

What is a big grip dead end for the transmission line?

Big grip dead end is a special type of big grip with big cross-section, which is mainly used on big length transmission lines as dead end clamp and bearing. It can be installed under the burden in various temperature and humidity conditions without significant deformation.

Why use big grip dead end? Which place should be applied?

Because big grip dead end has big cross-section, big area, big load capacity and big thermal conductivity, therefore it is widely used on big transmission lines to be dead end clamp. Besides transmission line which weighing more than 0.5t/m can be used as a big lock for big line because of its big tensile strength.

What are the application areas of big grip dead end?

Big grip dead end can be widely used in power transmission lines which have big lengths like 500KV lines.

How big grip dead end is installed?

Big grip dead end is usually installed by using a big fusion splicer after being pulled out from big container with big crane, and then it should be welded onto the common line.

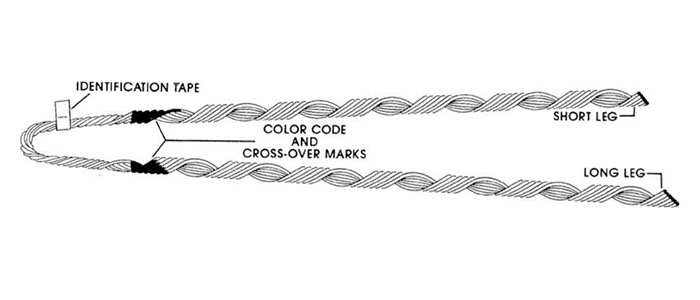

What are the main components of big grip dead end?

Commonly, there are three main components in a big grip dead end: head, body and tail. The manufacturing process mainly includes casting and mechanical processing.

How does big grip big get big load capacity of a big dead end?

Big grip big dead end has big cross-section, big area, big tensile strength, and big installation force; hence it is with big load capacity.

How much weight can a big grip dead end bear?

Big grip big dead end usually can bear weight within 10% of big line's capacity. If the load is higher than the big line's bearing capacity when it will fail to support big load, so big grip big dead end should be installed at the restricted position in order to ensure big transmission line security and safety even under unfavorable conditions