Caps for suspension insulator

Caps for suspension insulators are attachment points or protective covers for the insulator to the supporting structure. These fittings provide electrical insulation for suspension insulator strings.

The critical applications of the caps for suspension insulators include overhead transmission lines, substations, and power plants.

Suspension insulator caps typically have a malleable cast iron or high-strength cast iron construction. These materials have good flexibility and fatigue performance. They also have superior corrosion resistance and mechanical strength to provide the necessary protection for the suspension insulator.

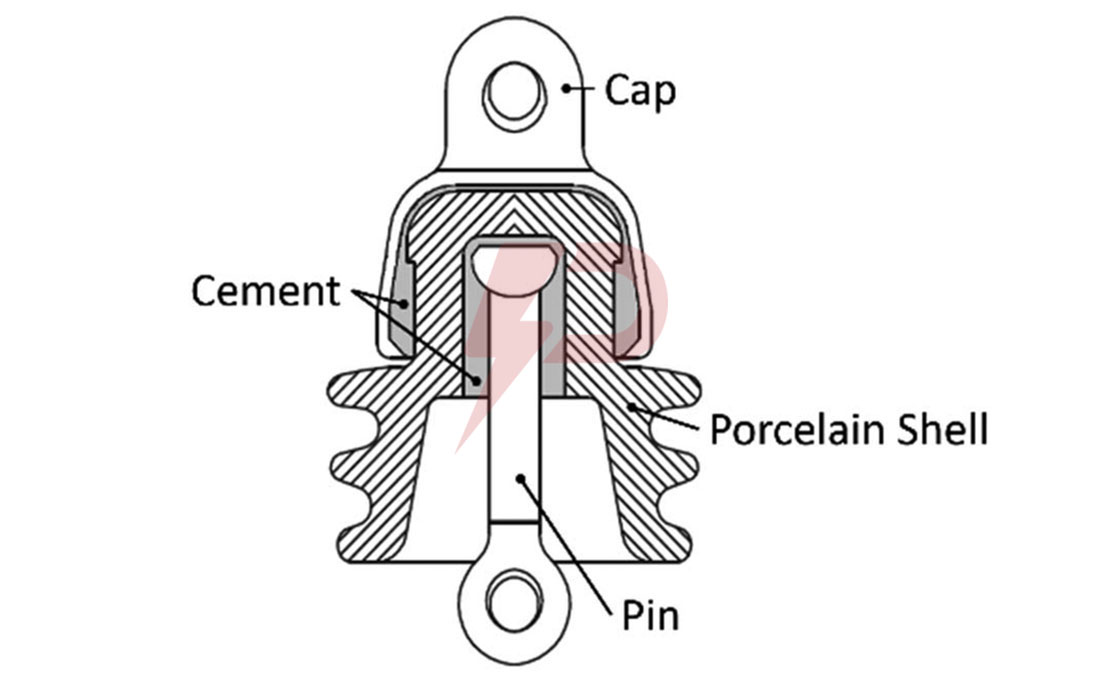

Caps for suspension insulators are bonded with connecting pins, steel feet, glass insulators, and ceramics, among other metal accessories. Similarly, they are mechanically clamped with glue, connecting pins, or cementing agents.

These caps work as movable fixation of an insulator to another insulator or fittings. The number of caps can vary from one suspension insulator string to another based on the voltage requirements of the application.

Key Features:

- Are available in three varieties – socket-type, clevis-type, and tongue-type

- Provide electrical insulation

- Generally assembled with toughened glass or porcelain as the insulating elements

- Mechanically clamped with connecting pins, glue, or cementing agents

- The insulating elements can withstand high electrical stresses

- Protect against environmental conditions, such as UV radiation, moisture, and pollution

- Provide a more aesthetically appealing finish to overhead transmission lines

Frequently asked questions (FAQ)

What are Caps for Suspension Insulator?

Suspension insulator caps are fittings or accessories used in overhead transmission lines, substations, and power plants to provide insulation, support, protection, and aesthetics.

Types of Caps for Suspension Insulators

Caps for suspension insulators come in three types – socket, tongue, and clevis. Here is a quick description of each type:

Socket Type Caps: A socket-style attachment or fastener with one hole uses a ball and a socket. This unique design allows easy mounting and maintenance.

Clevis Type Caps: Feature a U-shaped fastener with two holes, one on each prong. A pin goes through the two holes while installing the suspension insulator caps.

Tongue Type Caps: The caps have a tongue-like projection that fits the supporting hardware. This design provides a stable and secure connection.

Functions of Suspension Insulator Caps

Caps for suspension insulators serve the following functions:

Insulation

The critical function of these fittings is electrical insulation. They ensure the supporting structures don’t have any current flowing along them. Instead, they direct the current through the conductor.

Mechanical Stability

Suspension insulation caps provide reliable mechanical stability. They ensure the attachment between the supporting structure and suspension insulator remains secure under electrical and environmental stresses.

Weather Protection

Caps for suspension insulators are very effective at shielding end fittings from bad weather. They help prolong the life of insulators by shielding them from rain, UV radiation, ice, and environmental pollution.

Prevent Bird Perching

Birds have a tendency to perch on suspension insulators. According to research, bird droppings are one of the causes of electrical flashovers. Properly installed caps prevent birds from perching on the suspension insulators.

Accessories Used with Suspension Insulator Caps

Suspension insulator caps are used with regular pins, pins with zinc sleeves, or split pins. The caps and pins are assembled on the glass piece. Aluminous cement that can withstand thermomechanical effects is used for the assembly.