I-Beam Grounding Clamp

These clamps are designed for bonding cables and copper wires to flat metal objects in a wide range of applications. That makes them perfect for things like grounding telephone, satellite, and cable TV systems.

Typically crafted using premium-grade galvanized steel, l-Beam grounding clamps are valuable in creating a solid connection. The galvanized steel nuts and teeth on the bracket effectively penetrate paint and rust. This lends itself to a long-lasting component.

This grounding clamp is an economical solution to grounding systems. It offers reliable performance in a wide range of environments, including on l-beams, mobile homes, and even structural industrial steel beams.

The galvanized steel construction includes a set of teeth on a bracket. These are included in the design to help facilitate a tight connection. This is important for optimal electrical grounding. The mechanical galvanizing, which meets ASTM B695 standards, helps with durability and fights against corrosive elements.

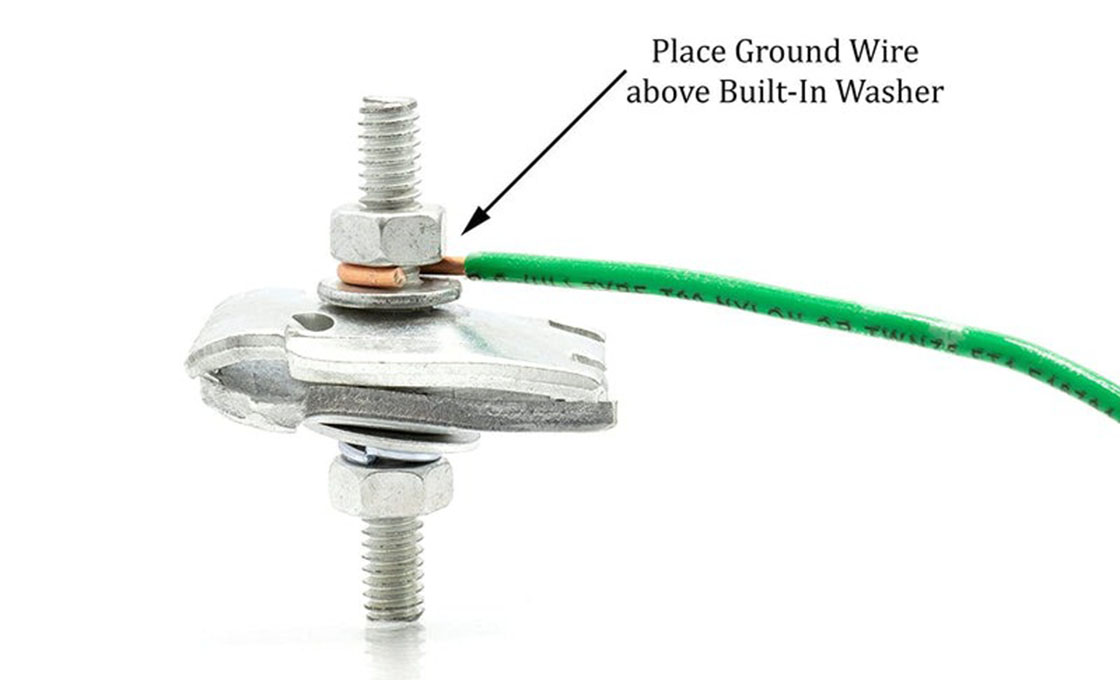

This clamp is compatible with ground wire up to 10 AWG. It works seamlessly with HD digital video as well as satellite and CATV grounding applications. Having undergone rigorous testing, it is UL-listed and approved for high-grade grounding.

Features

- Premium construction

- Suitable for a wide range of environments

- Compatible with up to 10 AWG ground wire

- Tested and approved for reliability

- Versatile application

- Corrosion resistant

- Cost effective

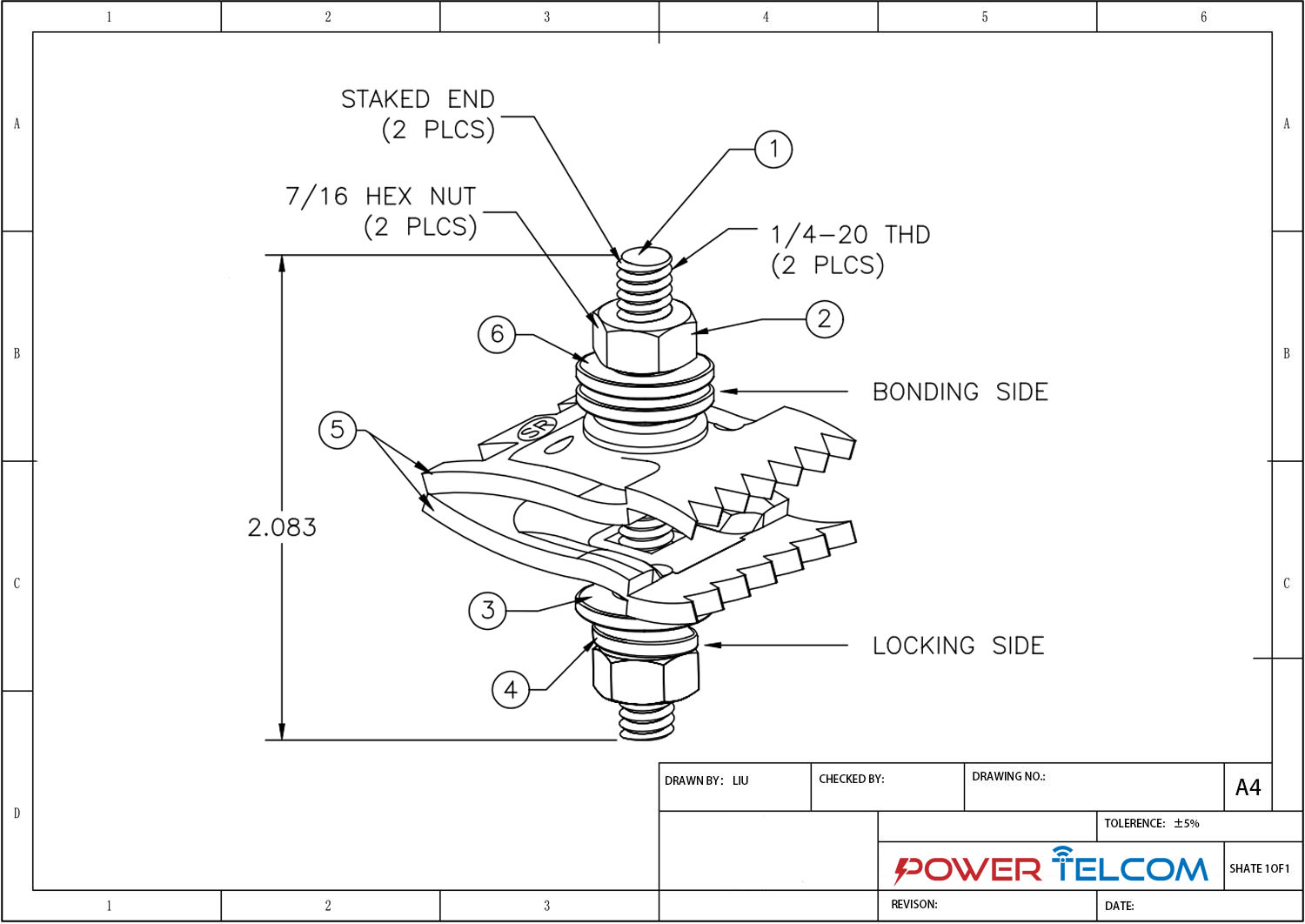

I-Beam Grounding Clamp Drawing

| Series | conductor Range | DiMENSiONS | BOLT SIZE | ||

| Min | Max | LENGTH WIDTH | HEIGHT | ||

| IGC8 | 8 SOL | 4 STR | 1-1/4 1 | 1-5/8 | 3/8 |

| IGC4 | 4 SOL | 2/0 STR | 1-5/8 1-1/8 | 1-3/4 | 3/8 |

| IGC2 | 2/0 SOL | 250 MCM | 2-1/8 1-1/2 | 2 | 1/2 |

I-Beam Grounding Clamp – A Simple Guide

Grounding in the realm of electrical systems plays a crucial role in safeguarding against potential hazards. The grounding clamp’s a crucial component that’s designed to establish a reliable electrical connection between grounding systems and structural steel l-beams.

Why Use I-Beam Grounding Clamps?

These clamps are instrumental, especially within electrical systems, when looking at improving safety and protection. They secure and help connect wiring to structural l-beams.

This creates low resistance pathways for electrical currents so that it can protect the system from potential issues. They‘re designed to adapt to different-sized l-beams for stability and reliability by offering adjustable mechanisms.

Types of I-Beam Grounding Clamp

There are various types of I-Beam grounding clamps available. This includes:

- C/U-Bolt Clamps

- Parallel Jaw and Adjustable Jaw Clamps

- Rod-to-Beam Clamps

- Clamps with threaded studs.

How Does an I-Beam Grounding Clamp Work?

These ingenious little tools work by securing connections between grounding electrodes and conductors. This creates a low resistance path for the electric current. They’re used to attach wires and cables by using tightening mechanisms for optimal contact, and that helps create a secure foundation.

In industrial settings, these clamps take electrical equipment and bond them to metal structures, which aid in a fault current’s safe journey. This makes them especially handy, especially when doing maintenance and repairs.

Component of an I-Beam Grounding Clamp

- Jaws: Ensures a secure grip

- Adjustment Mechanisms: customization for beam size

- Body: Provides structure and stability

- Connection Points: Serves as attachment points

- Fasteners: Firmly secures the clamp

Optional Features:

- Insulating Components: Prevent electrical conductivity

- Swivel Mechanisms: Allow rotational adjustment

- Spring-Loaded Adjustments: Automatically adapt to beam size

Factors to Consider When Choosing an I-Beam Grounding Clamp

You need to consider compatibility with the beam size that you’re using, installation, and the capability of the corrosive resistance of the clamp. You want a low-maintenance design that ensures stable and continuous performance. So, if you look at these factors collectively, they all contribute to a safer and more reliable grounding solution.