Compression H-Tap Connector

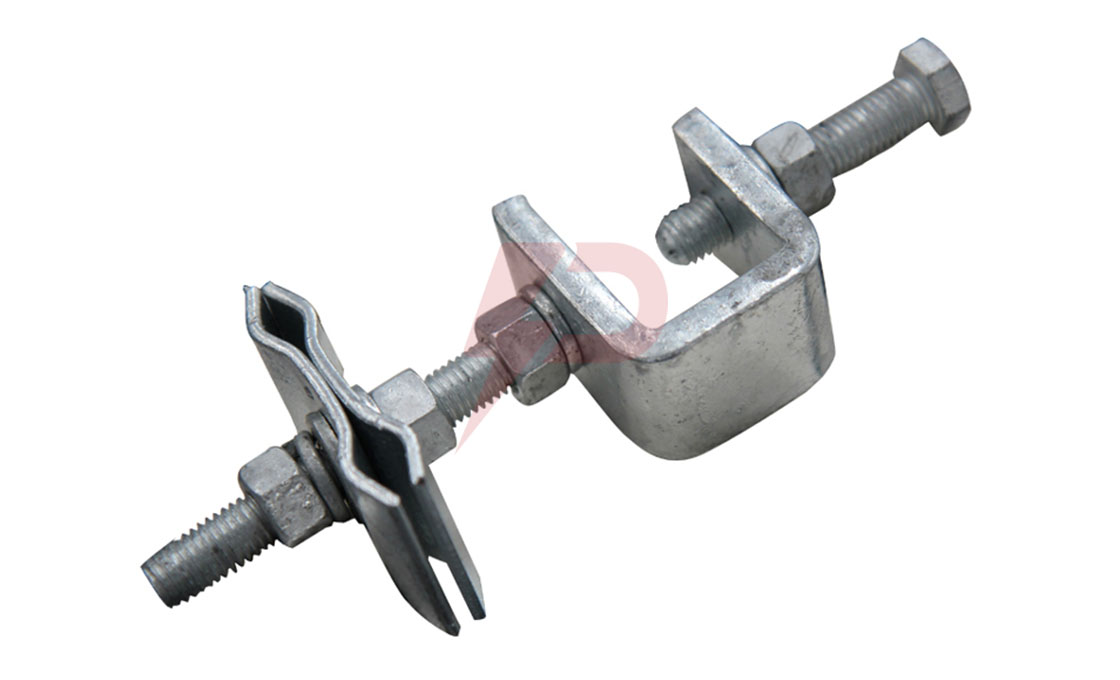

With a field-proven ribbed design, the compression h-tap connector is a range-taking mechanical device that connects a main overhead conductor (run) to a tap.

This range-taking connector is available in two variations commonly featured in overhead distribution lines. They include aluminum and copper compression h-tap connectors. H-tap aluminum compression connectors are compatible with aluminum-aluminum and aluminum-copper conductors. However, copper compression h-tap connectors are only used with copper conductors.

The primary function of h-tap compression connectors is making parallel or tap conductor connections. They provide simplified installation, lower connection costs, and more reliable connector performance.

Each groove (A & B) of the compression h-tap connector attaches to a conductor. One attaches to a run conductor and the other to a tap conductor to create a secure connection. The aluminum conductor is always on top of the copper conductor in an aluminum-copper combination.

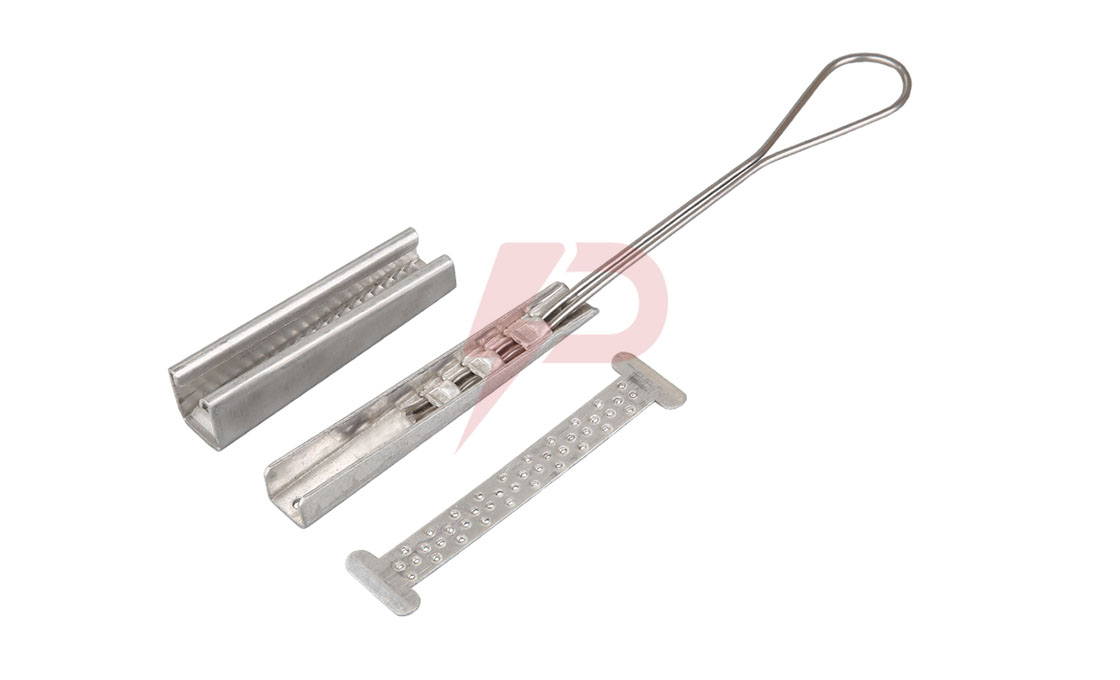

Electrical linemen use dies and standard compression tools to install compression h-tap connectors of varying sizes.

Important Features

- Corrosion-resistant heavy-duty aluminum construction

- Features A & B grooves for accommodating run and tap conductors

- Bendable taps on each side secure the conductors when folded

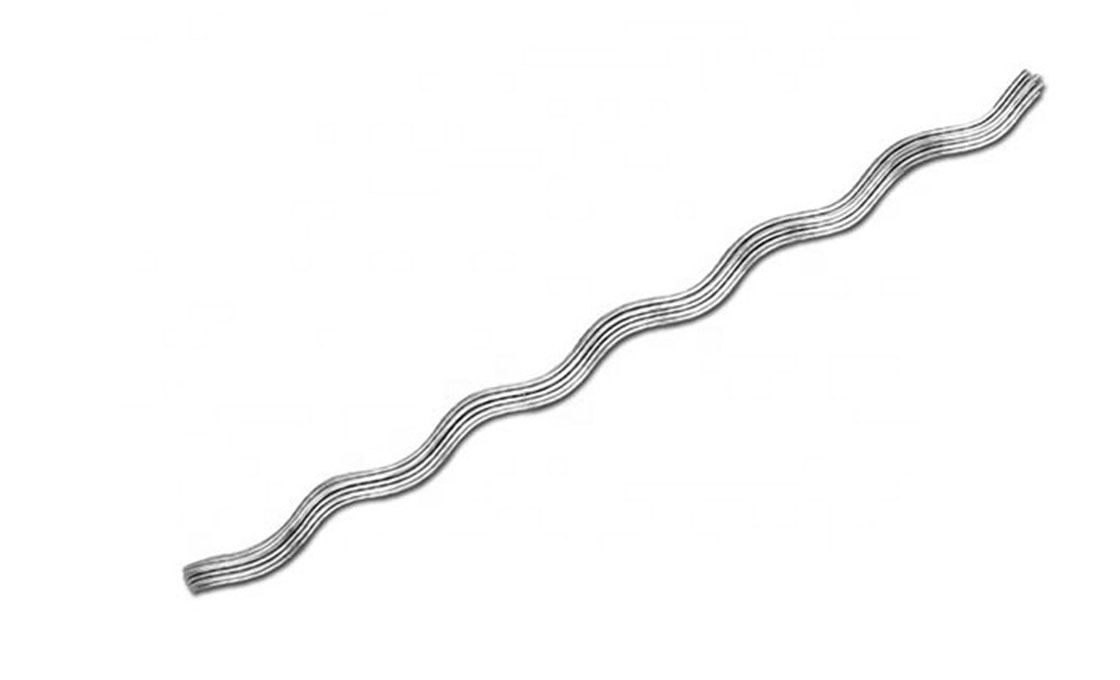

- Ribs are formable to provide a wide contact area

- Connection area is prefilled with oxide inhibitor

- Meets the required standards and temperature ratings

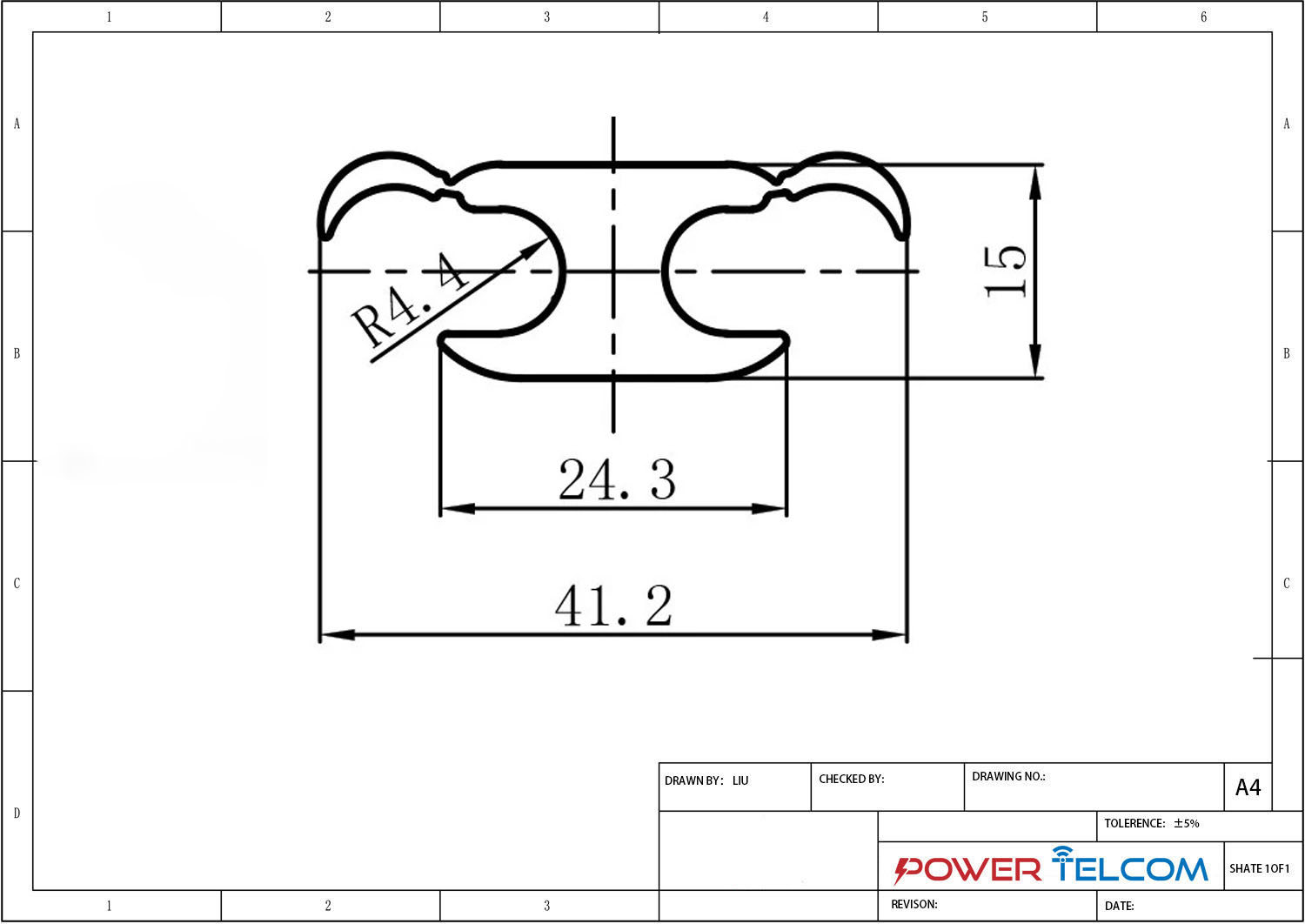

Compression H Tap Connector Drawing

Type | Hole 1(mm²) | D1(mm) | Hole 2(mm²) | D2(mm) | A(mm) | B(mm) | C(mm) | H(mm) | L(mm) |

| HTC-H1 | 16-35 | 4.8-8.2 | 16-35 | 4.8-8.2 | 7.1 | 24.3 | 41 | 15 | 38 |

| HTC-H2 | 50-95 | 8.3-14.5 | 16-50 | 4.8-9.5 | 13 | 36.6 | 60 | 22.5 | 48 |

| HTC-H3 | 95-95 | 10.0-14.5 | 50-95 | 10.0-14.5 | 5.4 | 36.4 | 63 | 22.3 | 64 |

| HTC-H4 | 95-240 | 13.0-22.5 | 16-70 | 4.8-11.5 | 14.3 | 50.5 | 80.4 | 30 | 51 |

| HTC-H5 | 95-240 | 13.0-22.5 | 70-150 | 11.6-16.0 | 9.4 | 50 | 83.5 | 32 | 51 |

| HTC-H6 | 150-240 | 16.2-22.5 | 150-240 | 16.2-22.5 | 5.1 | 50.5 | 90.6 | 30.3 | 89 |

What is a H-Tap Compression Connector?

It is a non-tension H-shaped clamp that connects conductors on overhead distribution lines. They work with high, low, and middle voltage aluminum and copper conductors.

Important Features of Compression H-Tap Connectors

These h-tap connectors have a mechanical compression design made of aluminum. Contact with run conductor and tap conductor is made mechanically to improve the integrity of the connection and to avoid distorting the conductor’s shape. They are mainly used for copper-aluminum and aluminum-aluminum conductor connections. Standard compression tools are typically used by electrical linemen for installation.

Types of Compression H-Tap Connectors

H-tap compression connectors are classified according to the construction material. The two common materials used are aluminum and copper. Aluminum compression h-tap connectors have wider compatibility than their copper cousin. They can be used for aluminum-copper and aluminum-aluminum combinations. The copper variant is applicable in a copper-copper conductor application.

How does a Compression H-Tap Connector Work?

Used in overhead transmission lines, compression h-tap connectors allow linemen to easily and safely attach run conductors to tap conductors. The installation of h-tap compression connectors is typically easy and quick. It involves the preparation of the conductors, positioning of the grooves, compression of the fold-in tabs, and inspection. They ensure stronger conductor combination for safer power distribution.