Ground Screw Anchor

Ground screw anchor, also called Ground screw, foundation screw or Penetrator Anchor, can be regarded as an innovative product for the construction industry. This is because it addresses the need for swift installation of structures and responds to the growing demand for environmentally safe approaches in the construction industry.

The screw is designed to replace the laborious work of having to set concrete footings for various structures. Instead of having to invest a lot in ballast, cement, and other materials, ground screws will just need to be fixed in the ground and will play the same purposes as that of concrete footings. This will save you money and offer a sustainable construction solution.

To make sure the screws offer a solid and robust solution, they are usually made from Q235B Steel and feature a continuous welded helix, ensuring durability and reliability. They also have a galvanized finish parallel to the ASTM123. This makes sure that the screws are protected from corrosion and hence ideal for any environment.

The working of this screw is such that it has to be twisted into the ground using mechanical drivers, providing immediate stability and load-bearing capacity. The screw can be used with a range of accessories, including flanges for connecting structures, ensuring versatility and adaptability to different project requirements.

Key features:

- Features a continuous welded helix construction

- Made from Q235B Steel

- Hot-dipped galvanized (ASTM123 standard)

- ICC Certified

- Different Models and Sizes

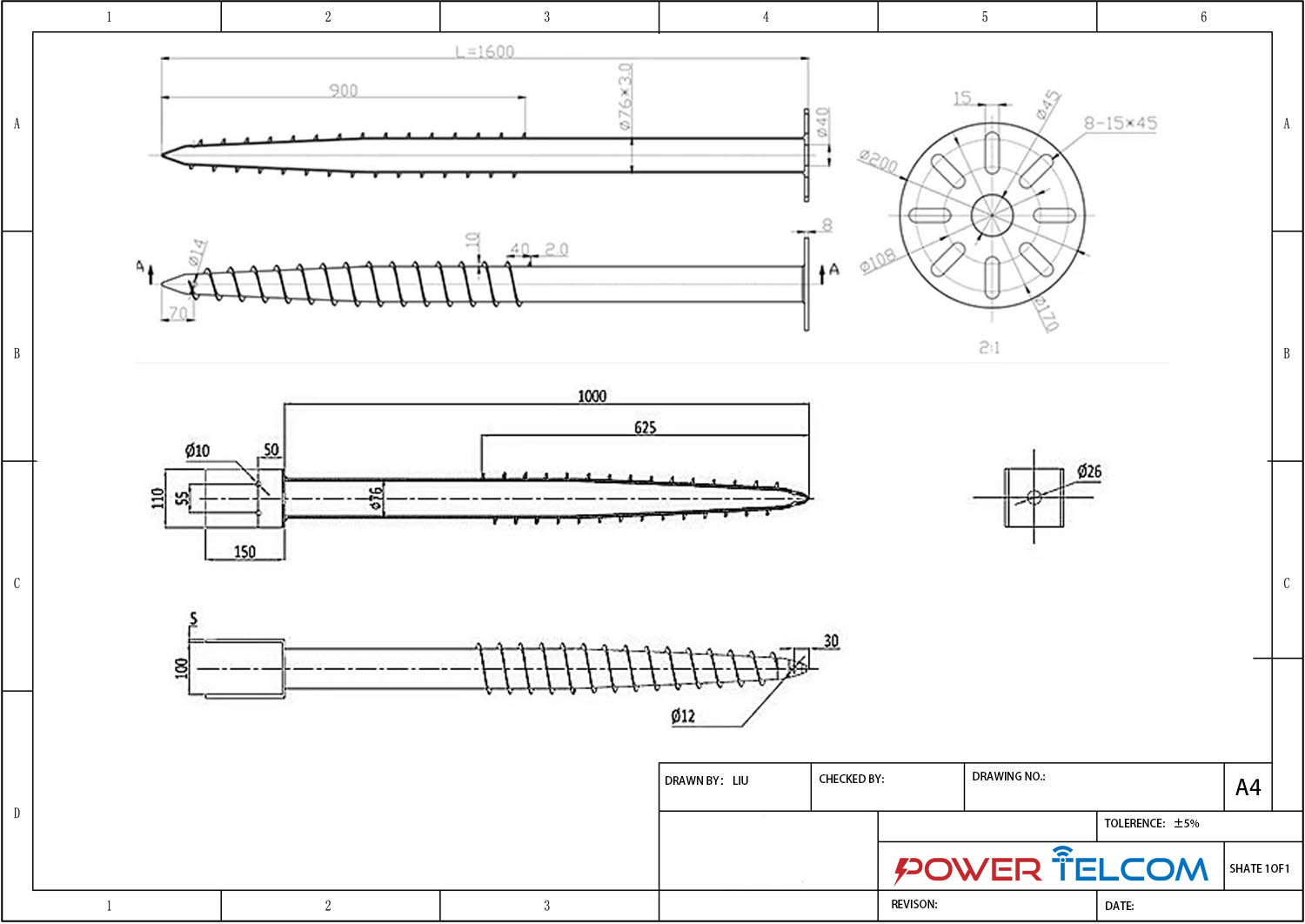

Ground Screw Anchor Drawing

Lenth*φ*Thickness | Weight | Packing | Total Weight |

L1600*76*3.0 | 9.8 kg | 180 PC/pallet | 1800kg |

L1800*76*3.0 | 10.72kg | 160 PC/pallet | 1750kg |

L2000*76*3.0 | 11.8 kg | 150 PC/pallet | 1805kg |

L2200*76*3.0 | 12.8kg | 140 PC/pallet | 1830kg |

L2500*76*3.0 | 14.25kg | 120 PC/pallet | 1745kg |

L2800*76*3.0 | 15.7kg | 110 PC/pallet | 1760kg |

L3000*76*3.0 | 16.8kg | 110 PC/pallet | 1885kg |

Frequently Asked Questions (FAQs)

What is a ground screw?

The ground screw might be the ideal solution to the current environmental concerns when it comes to hosting of structures. The screws are made of Q235B Steel that has been through a rigorous galvanizing process that is in accordance to ASTM123. This ensures that the screws have top-notch stability and durability that can withstand the test of time.

What is the function of the ground screws?

The product simplifies the foundation-building process with its innovative design. By eliminating the need for extensive excavation and curing time associated with traditional concrete footings, ground screws offer immediate load-bearing capacity upon installation. The uniqueness of spiral patterns brings superb stability and performance into their application, which facilitates quick and efficient project completion with minimal to no footprint.

How to install ground screws?

The process of putting up the ground screw is simple, requiring the use of mechanical screwdrivers to rotate the screws into the ground. Appropriate downward pressure must be applied to advance the screw into the soil effectively. A key reliability of this product is its ICC certification, indicating compliance with building codes, and a hot-dipped galvanized finish for corrosion resistance.

What are the applications of the ground screws?

From the private structures of a home to the public installations of a carport and even to the temporary projects, these screws offer stability and endure everything all through these distinct settings. Moreover, their compatibility with the solar installations is a further proof of their adaptability, giving a firm basis for renewable energy projects.

The ground screw is designed to survive in the severe conditions of today's construction and together with the environmental consideration, it has set a good benchmark for foundation solutions in the construction industry.