Insulator Tie

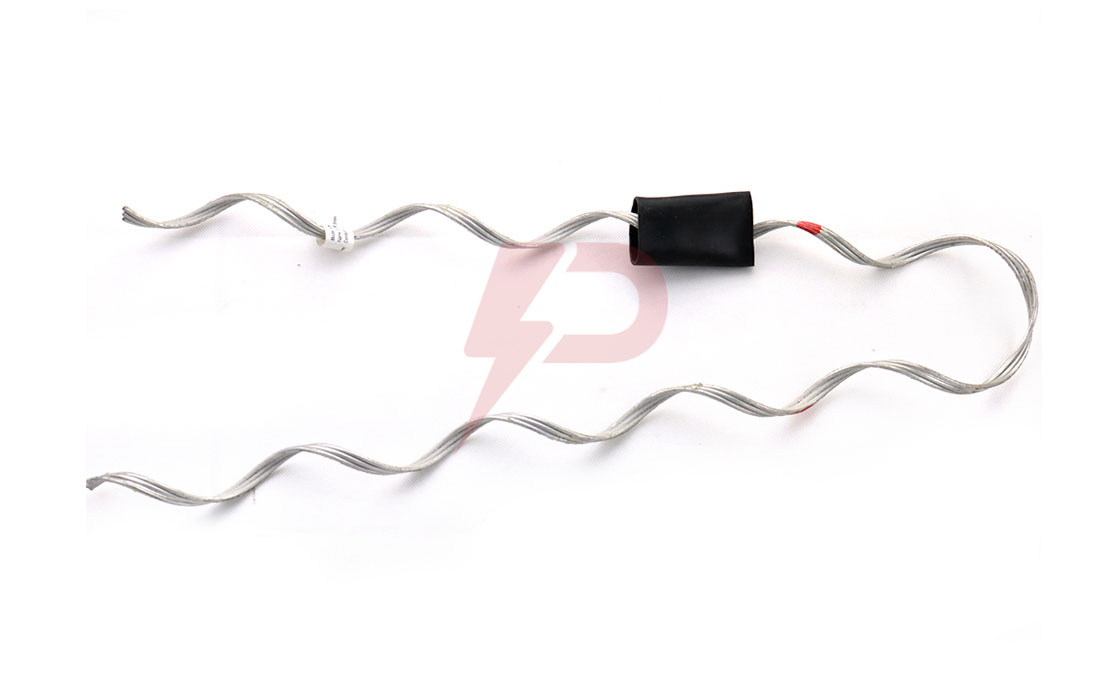

Insulator ties are specialized formed wires designed to secure electrical conductors to various types of insulators in overhead power distribution systems. These preformed wire components consist of aluminum, steel, or composite materials with a unique helical design that provides superior grip and protection. Insulator ties come with elastomeric tubes that create a protective cushion between the conductor and insulator, preventing abrasion damage and extending system longevity.

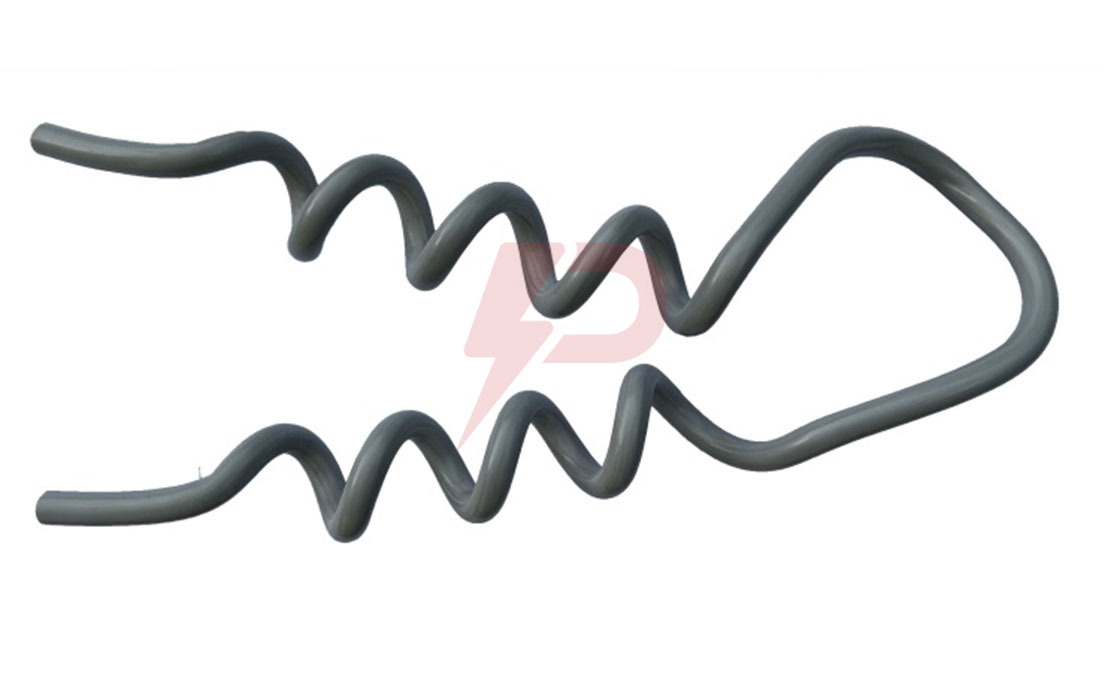

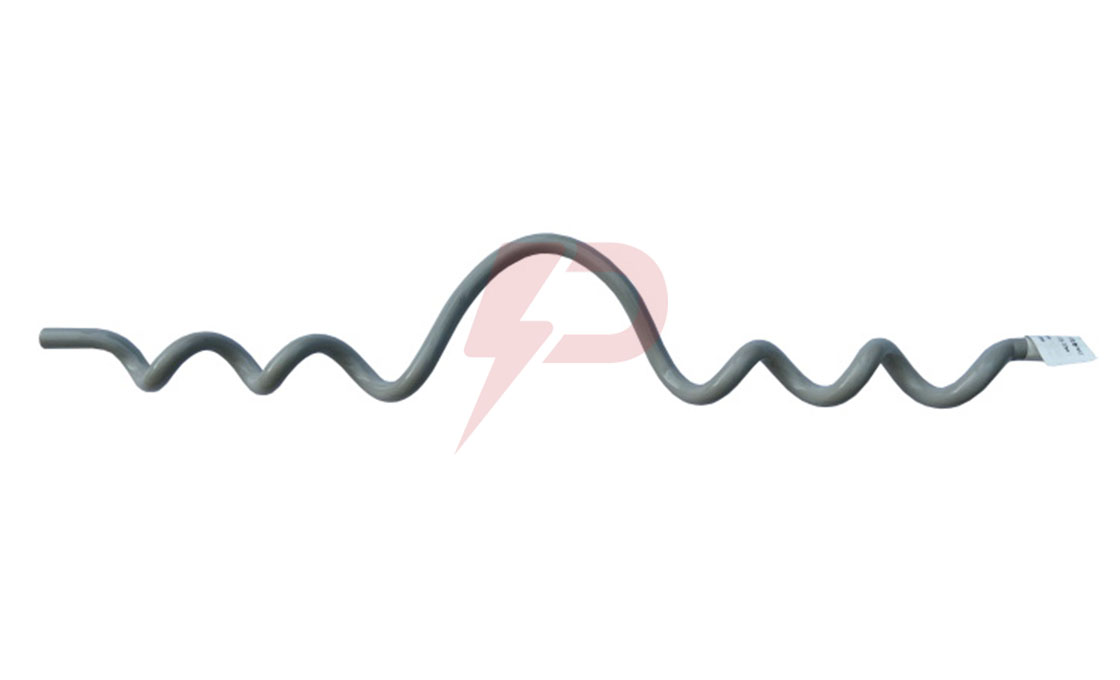

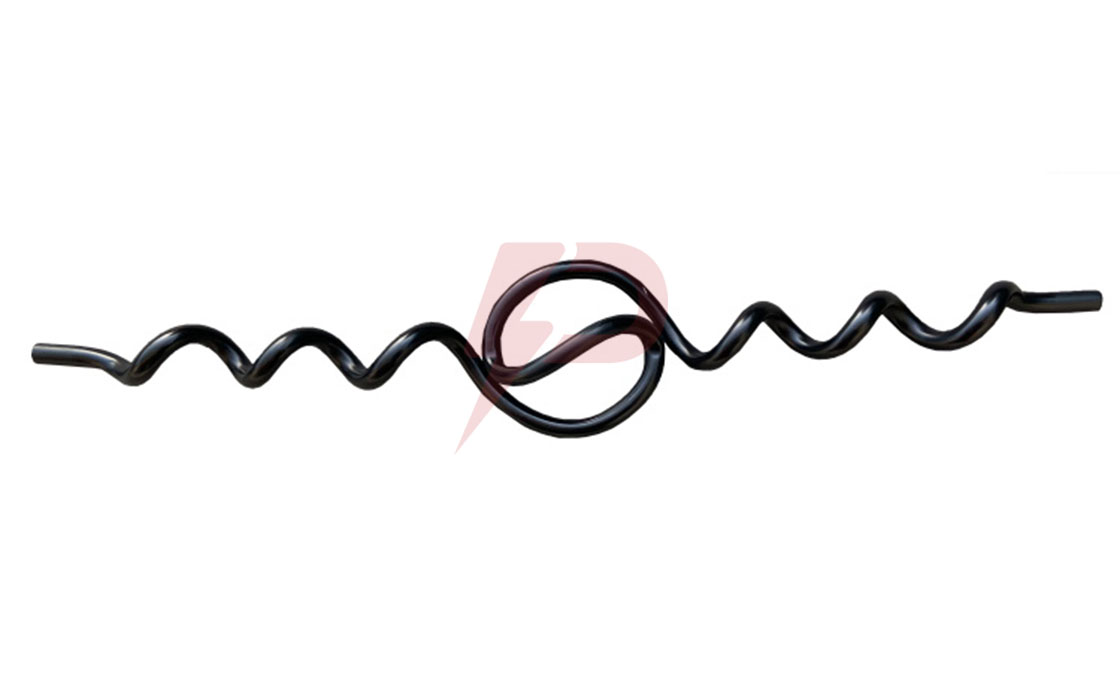

The three main types – Top Ties, Side Ties, and Spool Ties – each serve specific mounting configurations. Top Ties secure conductors to the top groove of pin insulators, Side Ties fasten conductors to side grooves of interchangeable headstyle insulators, while Spool Ties are used with spool/shackle insulators for low voltage applications. Each type is engineered to provide controlled movement while maintaining secure attachment under various environmental conditions.

Key Features:

• Pre-contoured design ensures uniform grip and easy “snap-on” installation

• Built-in elastomeric cushioning prevents conductor abrasion and damage

• Accommodates line angles up to 10 degrees in vertical orientation

• Superior vibration dampening compared to traditional hand-tied methods

• Available in various sizes to match different conductor and insulator combinations

• Provides resilient support allowing controlled conductor movement while maintaining position

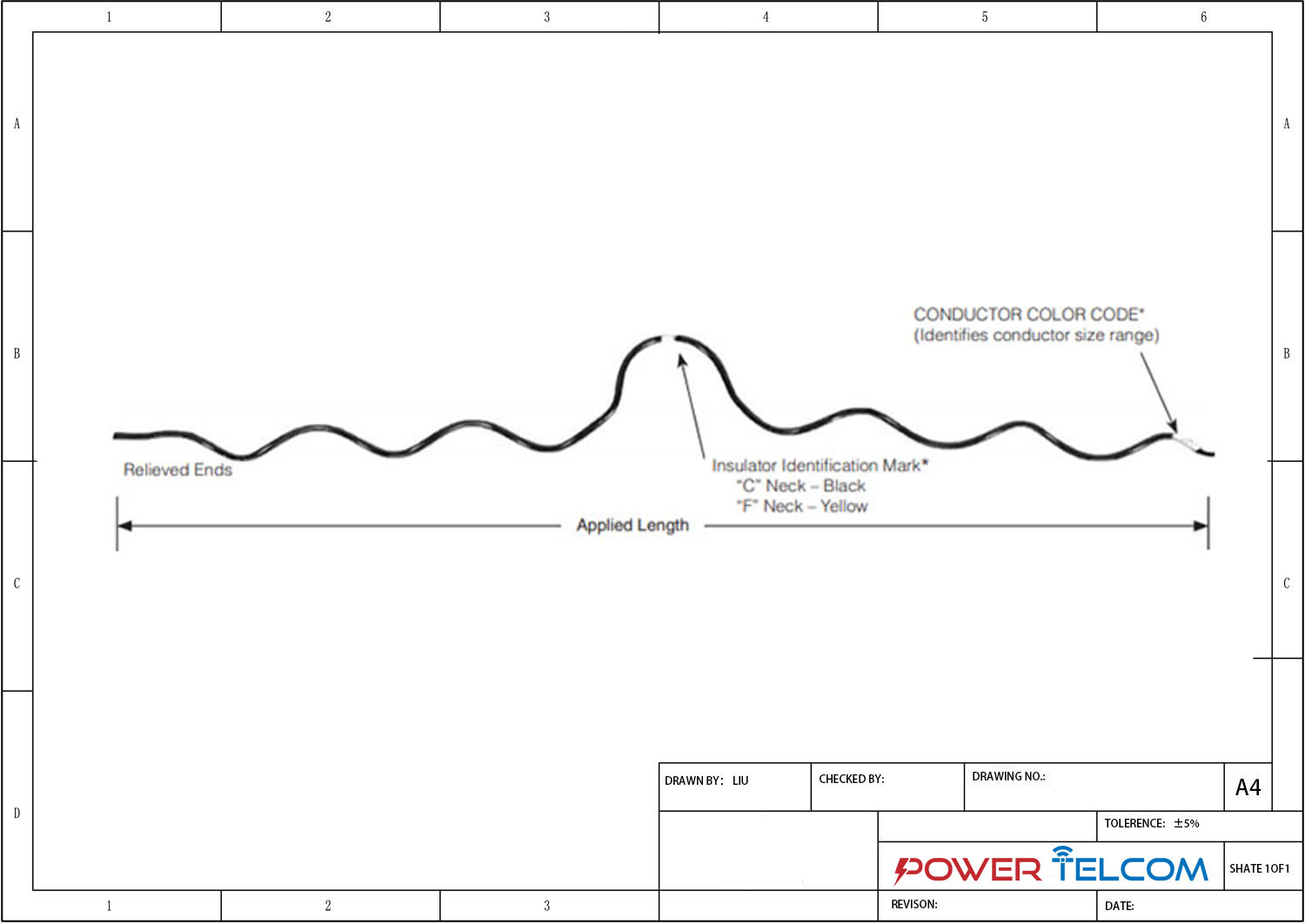

Insulator Tie Drawing

| Catalog Number | Diameter Range (Inches) | Applied Length (Inches) | Insulator Identification Mark | Color Code | |

| Mi n. | Max. | ||||

| CST-24 | .278 | .315 | 24 | Black/None | Purple |

| CST-25 | .406 | .459 | 25 | Black/None | Blue |

| CST-27 | .460 | .520 | 27 | Black/None | Orange |

| CST-28 | .521 | .588 | 28 | Black/None | Red |

| CST-31 | .589 | .665 | 31 | Black/None | Purple |

| CST-33 | .666 | .755 | 33 | Black/None | Brown |

| CST-35 | .756 | .858 | 35 | Black/None | Red |

| CST-36 | .859 | .968 | 36 | Black/None | Blue |

| CST-38 | .969 | 1.096 | 38 | Black/None | Green |

| CST-40 | 1.403 | 1.585 | 40 | Black/None | Black/None |

Frequently Asked Questions (FAQ)

What is an insulator tie?

An insulator tie (distribution tie) is designed to bundle conductors to spool or pole top insulators. Made from aluminum-clad steel wire, PVC, or semi-conductor materials, it secures different types of conductors including ACSR, Compacted ACSR, All Aluminum, Aluminum Alloy, or plastic jacketed conductors.

What are the main types of insulator ties?

There are three primary types of insulator ties: top ties (securing conductors to top groove of pin insulators), side ties (mounting conductors to side groove), and spool ties (attaching conductors to spool insulators).

What are the key components of an insulator tie?

An insulator tie consists of four main components: the tie (aluminum component taking conductor force), pad (insulating plastic cover), identification tag (showing specifications), and color codes (inner for conductor size, outer for insulator size).

How should tie wires be installed on insulators?

Tie wires should be attached to insulators with clockwise twists. When wrapping around conductors, maintain clockwise direction on each side to prevent untwisting. The tie should have six full turns around the conductor plus length for insulator attachment.

What advantages do preformed ties offer over hand ties?

Preformed ties provide better fastening with rebound resilience, higher strength from aluminum-clad steel construction, reduced shimmy during wind flow, easier installation through machine-formed helical shapes, and superior radio interference voltage (RIV) characteristics.

What are the technical requirements for insulator ties?

Insulator ties must meet specific mechanical strength requirements, match rated voltage of transmission lines, comply with ANSI class specifications (like C29.5), have appropriate weight and impact strength, and match conductor size through proper top groove radius.