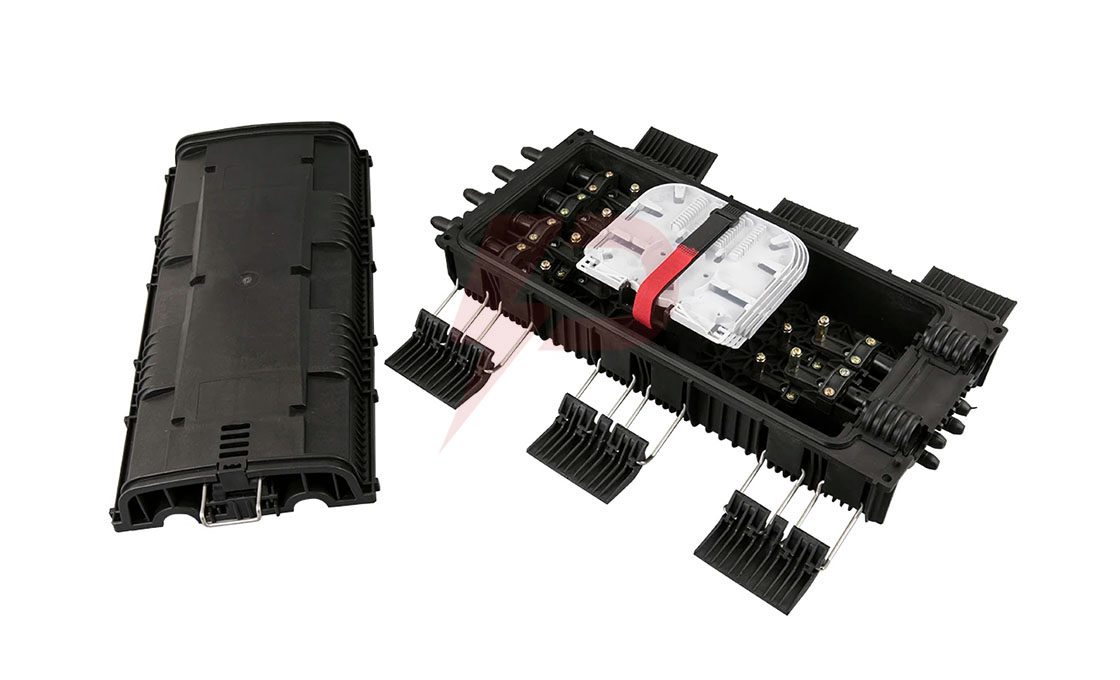

Fiber Optic Closure

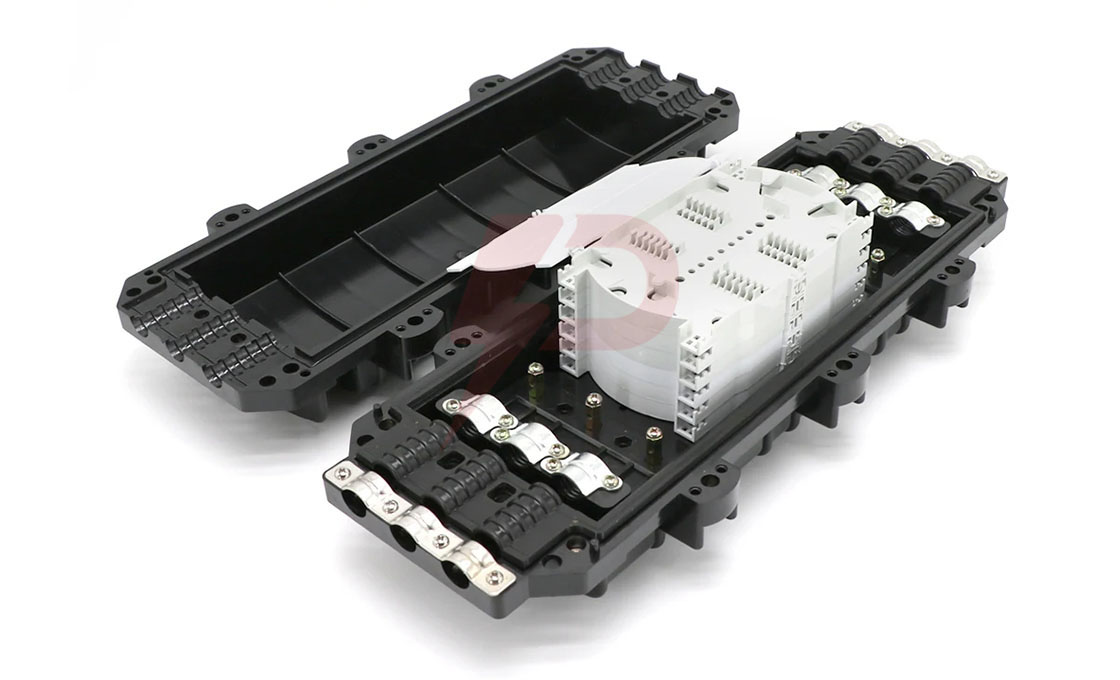

Fiber optic closures are useful devices, sometimes called fiber optic splicing closures. Their main use is to safeguard fiber optic cables by connecting optical fibers, whether indoors or outdoors.

These small box-like tools are made from durable plastic that can shield parts of the cabling from possible threats in their environment. They’re mainly used in places like data centers and telecommunications companies to protect their cables from being damaged by dust, moisture, or dampness.

Since the introduction of fiber optic closures, securing cables has never been easier. All you have to do is remove the covering from the cables so you can splice the fibers in the closure to ensure they’re fully sealed and no water can get into them.

Two types of fiber optic splice closures can be ranged: dome and inline. Some have inputs only at the bottom, while others have them at both ends. Regardless of which one you choose, they all have strong plastics and splice cassettes on the interior, which can withstand environments between -40 °C and +65°C.

Without fiber optic closures, communication wouldn’t be as developed as it is today, as they’re the leading protector of high-speed data transmission.

Key Features:

- 1 to 4 round ports, depending on the model you choose

- Water and dust-resistant

- Suitable to handle bunchy and ribbon fiber

- It can be used for wiring and storing fiber

- Possible dimensions 150x230mm

- Entry and exit sealing type

- Secure and straightforward installation

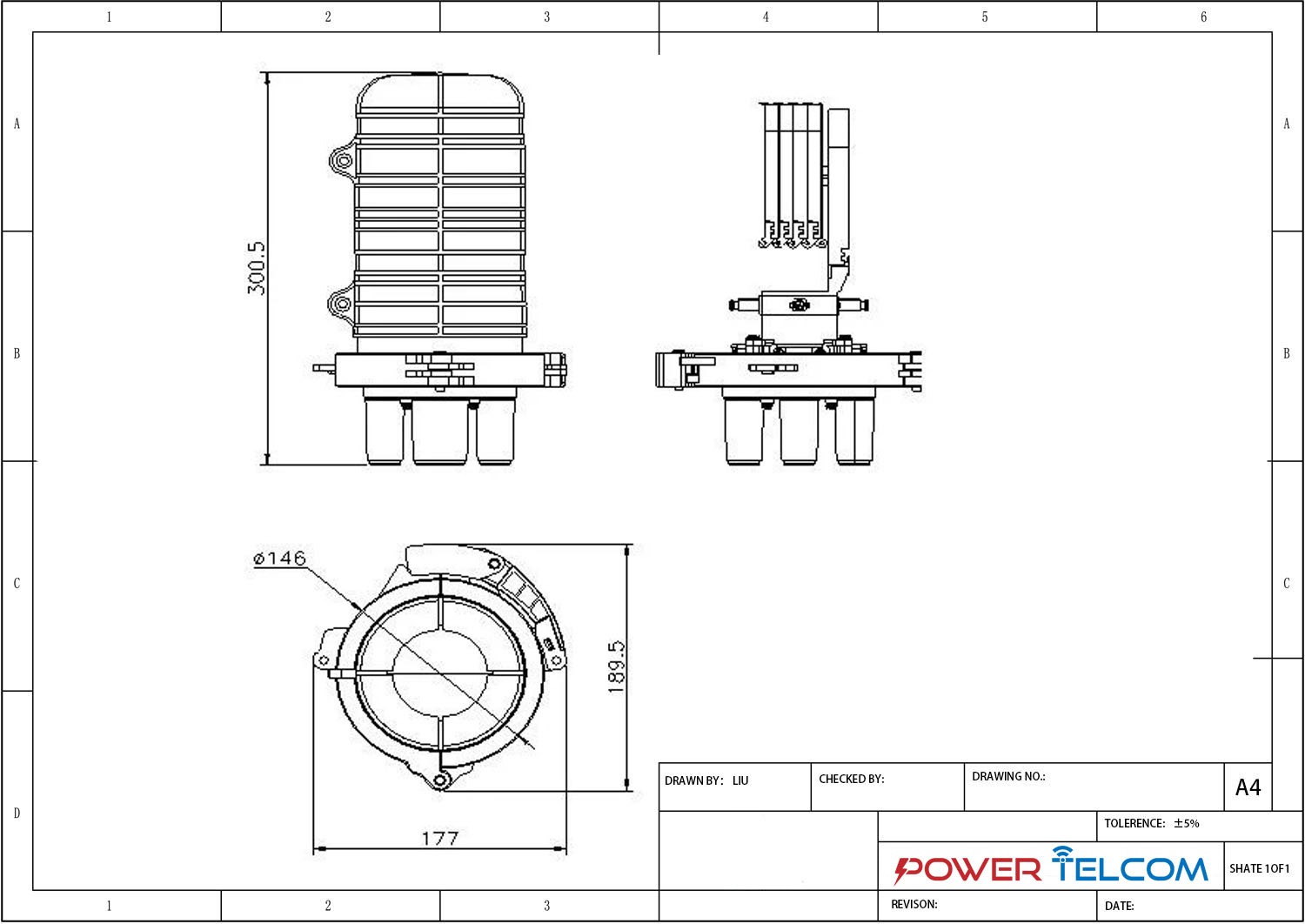

Fiber Optic Closure Drawing

Color | Black | ||

Dimension (mm): | 400(H)×135(Φ)mm/530(H)*150/*438(H)*225mm support Customize | ||

Protection class | IP66/IP68 | ||

Seals | Mechanical seal | ||

Material | High quality PC, ABS, PPR material optional, | ||

No. of Cable Inlet/Outlet | 2 in 2 out/ 1in 3 out/1 in 4 out Optional | ||

No. of Fibers per Tray | 24 cores per tray | ||

Max. Number of Trays | 6 |

Fiber Optic Closure: A Simple Guide

Regardless of the climate you live in, fiber optic closures are essential to keep your outdoor and indoor cables safe. They give you space to fuse splice optical fiber and provide protection from their setting’s challenges, from bad weather to excess dirt.

While fiber optic closures are relatively easy to set up if you know what you’re doing, it can be difficult for some people, so getting help from a professional is always helpful.

In this guide, we’ll give you a full breakdown of fiber optic closures, some of their features, and how to use them.

What Is a Fiber Optic Closure

Fiber Optics are instruments used to hold and create room between spliced fiber optic cables so they can endure rough conditions. Since these cables are quite sensitive, it reduces the chance of any possible damage, so network communications can always remain strong even in the event of a storm.

Fortunately, some of the primary elements, like an outer shell made of polymer, a strong sealing system, and an organized splice tray, are added defense layers for the product.

What Is the Function of a Fiber Optic Closure?

Fiber optic closure has two main functions. The first is sealing fiber optic cables together so they don’t disconnect from each other if it’s windy outside.

If they were to disconnect, they could become damaged, and the connection could be seriously weakened or cut off completely.

Secondly, the device is used as a shield from potentially damaging contaminants that could hinder the connection. These include mud, water, debris, dust, and much more.

The Types of Fiber Optic Closures

There are two different types of fiber optic closures: horizontal fiber optic closures and vertical fiber optic closures.

Below, you can find a brief breakdown of each.

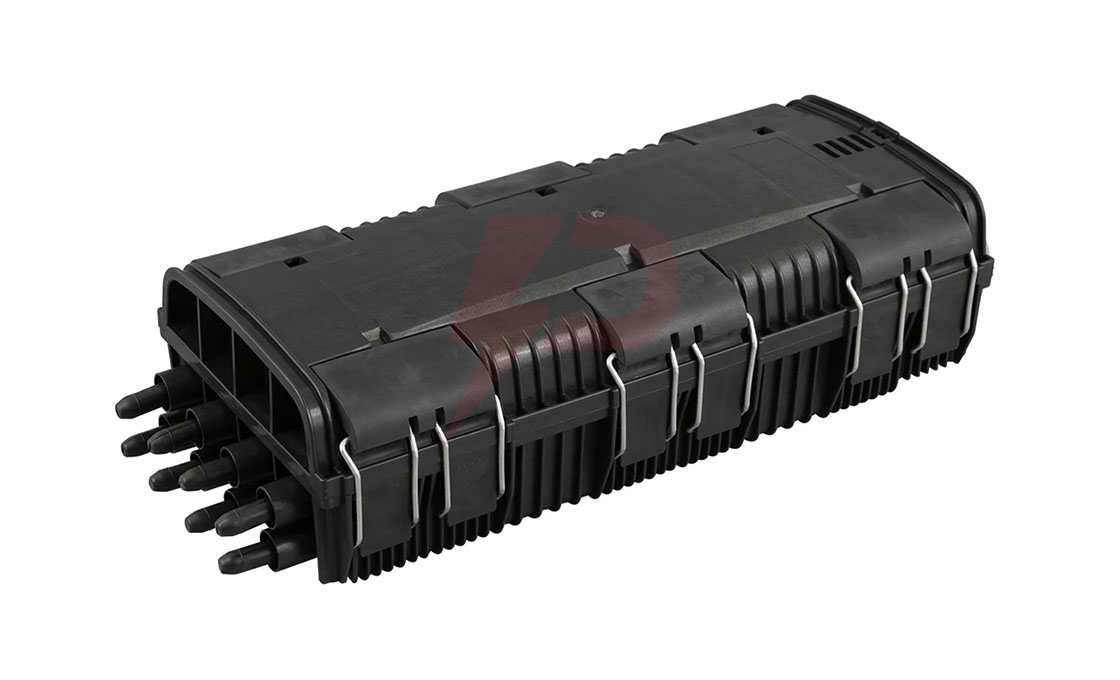

Horizontal Fiber Optic Closures

Horizontal fiber optic closures are often used for underground fiber optic cable connections. They look like round containers with usually one splice tray, although some have more, depending on the model. Their standard fiber count is usually either 12 or 24.

Considered dust and waterproof, horizontal fiber optic closures are considered extremely strong as long as they’re fitted tightly so they don’t blow away if it’s windy.

Vertical Fiber Optic Closures

One of the key differences of vertical fiber optic closures is that they are shaped like a dome; these are more advanced than the horizontal version because of the increased demand for a larger holding volume.

Vertical fibers are more protected because they’re used in more challenging conditions and hold more wires. You can buy them in a range of different inlet and outlet ports and with multiple splice trays.

How to use Fiber Optic Closures

Depending on the type of fiber optic closure you buy, there may be a different process for setting it up, but by and large, they follow the same procedure.

You can always seek help from a professional installer if you’re unsure.

Follow these installation steps with your new fiber optic closure if you need help.

Step 1: Locate the cables you want in the fiber optic closure and clean any excess dirt off them.

Step 2: Remove the defensive covering on the wire and pick out the area of each of them you want to wrap together.

Step 3: Next, you’ll want to begin splicing the chosen wires together; you can either hook or wrap them together. The ideal method will depend on the type of wires.

Step 4: Make sure the wires are tight enough together so they don’t unwind, and then seal them in the chosen fiber optic closure.

Step 5: Finally, you should test the connection of the wires to guarantee the fiber optic closure is working properly and check to see if there’s any way it can be damaged before you hook it up to the chosen location.

Key Features of Fiber Optic Closures

Before buying a fiber optic closure, you can learn about its key features below:

- It’s able to hold any type of fiber optic cable.

- It has a low bend radius, so the cables don’t get damaged.

- Adaptable splice trays that can hold multiple cables at a time.

- It contains a strong cable termination system, so it can survive long periods without repair.

- You’re able to purchase them with different numbers of cable ports for a high network capacity.

Factors to Consider When Choosing a Fiber Optic Closure

There are some things you should consider before you decide on what fiber optic closure you want to purchase, such as:

- The number of cable ports, so you know how much capacity it can hold.

- The sealing method is important because you want to make sure it will suit the environment you want to fit it in.

- The splicing type since they have an impact on the capacity a splicing tray can hold.

- The materials used for building the fiber optic close to ensure it’s strong enough to defend the cables from damage.

- The compatibility of the device, so the design of your cables will fit your fiber optic closure.

A leading Fiber Optic Closure Manufacturer in China

Powertelcom specializes in ADSS and OPGW related accessories in China. With more than a decade of experience in the industry, we have built up a strong customer base in many countries.

At Powertelcom, we design and manufacture quality Fiber Optic Closures in China. Feel free to contact us and we will deliver according to your requirements.