Spiral Vibration Damper

A spiral vibration damper is used to lengthen the cable line’s lifespan. It reduces wind-induced vibration or Aeolian vibration in cables such as the optical ground wires (OPGW), overhead shield wires (OHSW), and delicate cables and conductors up to 0.75 inches (diameter).

Made of weather-resistant PVC material, Powertelcom SVDs offer the perfect solution against the effects of wind on the cable. The material is also ideal because it does not eat away or wear down the cable. It’s also very easy to install (more on this later).

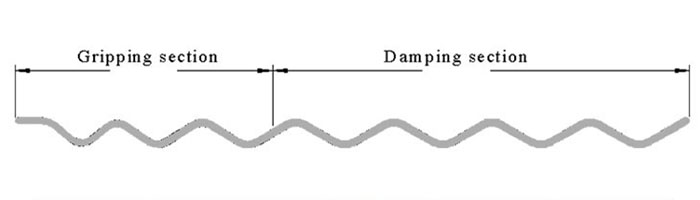

These dampers have a large, spiraling part known as the damping section and a smaller part called the gripping section. This design is suitable for reducing the Aeolian vibration occurring on the line by absorbing and dispersing the vibration across the damping section of the spiral.

The gripping section gently holds the SVD in place without damaging the cable.

At Powertelcom, we use cutting-edge technology to make sure our SVDs work optimally for the specified conductor range and cable diameter. Every damper is marked to show its conductor range and color-coded to show the cable diameter size range.

If you are not sure, which to buy, our team of experts will guide you to the best SVD for your application.

Model | Cable Diameter(mm) | PVC wire(mm) | Total Length(mm) | Gripping Length(mm) | Weight(kg) |

FTL-6 | 4.40-6.30 | 12.8 | 1160 | 150-200 | 0.24 |

FTL-8 | 6.35-8.30 | 12.8 | 1240 | 170-220 | 0.26 |

FTL-11 | 8.30-11.70 | 12.8 | 1300 | 250-300 | 0.28 |

FTL-14 | 11.71-14.30 | 12.8 | 1350 | 250-300 | 0.30 |

FTL-16 | 14.31-19.30 | 15.8 | 1640 | 330-350 | 0.63 |

Spiral Vibration Dampers: The Ultimate Review

Wind-induced vibration also called Aeolian vibration of overhead cables is a common occurrence throughout the world.

Aeolian vibration is a major issue in transmission lines because it results in fatigue failure of conductor strands or equipment associated with support such as cable suspension clamps, deadends, spacers, spacer dampers, etc.

The figure below shows the effect of Aeolian vibration on a stranded wire.

What is a Spiral Vibration Damper (SVD)?

A spiral vibration damper is used to lengthen the cable line’s lifespan. It reduces wind-induced vibration or Aeolian vibration in cables such as the optical ground wires (OPGW), overhead shield wires (OHSW), and delicate cables and conductors up to 0.75 inches (diameter).

When strands break their share of electric current is shared with other strands causing conductor fatigue. Using SVDs is the easiest and cheapest way to prevent this kind of breakage from happening.

Spiral Vibration Dampers Applications

As the length and tension of a cable line increases, its self-damping properties decrease. Generally, the self-damping abilities of a strand are related to the looseness of the individual strands or how they can freely move. Therefore, vibration activity is more prevalent in the coldest months when the cable is tighter.

This issue is resolved by introducing additional damping using damping devices such as Spiral vibration dampers (SVDs). The SVDs reduce the stress in the conductor strands.

The intensity needed to bring about Aeolian vibration also varies. It depends on factors like the topography of the area, height and direction of the cable, span length, and types of conductors and clamps. For example, the smaller the diameter of the cable or conductor, the higher the frequency of the vibration. The SVDs should therefore meet the requirements for wind velocity range or frequency range.

Applications

- Overhead Shield Wires (OHSW)

- Optical Ground Wires (OPGW) and Overhead Ground Wires (OHGW)

- Conductors between 0.25 to 0.75 inches

- Distribution spans

- Spans over 800 feet.

Features of Spiral Vibration Dampers

- Reduces weather-induced vibrations

- Conduction-friendly spiral design

- Weather resistant, non-corrosive PVC

- Ideal for cables up to 0.75 inches

- Suitable for different frequencies

- Color coded to show cable size diameter range

- Easy installation

Parts of the Spiral Vibration Damper

- The Length: This is the entire length of the SVD. Different conductor sizes require different lengths.

- The damping section: It absorbs and disperses the Aeolian vibration by creating an action movement that neutralizes the vibration wave.

- The Gripping Section: This part gently holds the SVD in place without damaging the conductor.

How To Install Spiral Vibration Dampers (SVDs)

The spiral vibration dampers need to be placed in a suitable position to ensure success. They should be installed near but not in contact with the following support equipment (leave a gap about 6-8 inches).

- Armor rods

- Cable suspension clamps

- Deadends

- Or other electrical hardware.

SVD installation is easy and, more or less, follows the same procedure for all manufacturers.

Step 1: Install ADSS (All Dielectric Self Support) cables correctly between poles or any securing points along the lines. This should be done according to the manufacturer’s instructions.

Step 2: Hold the SVD next to the ADSS cable with the gripping end away from you and the damping area closer to you. This is done to determine the proper gap to leave before you start installing.

Note: As mentioned earlier, the SVD should never touch the armor rods or any hardware at the end. There should be an approximate 8-inch gap from the ends of the hardware to the SVD.

Step 3: Install the SVD by wrapping it around the line starting from the gripping end or tighter end fast. This is done until the whole SVD length wraps around the cable.

Summary

The spiral vibration damper is very vital in reducing the Aeolian vibration and increasing the lifespan of transmission lines. Remember, these problem-causing vibrations are caused by smooth winds that occur day to day (2-15 mph). This means that the SVD should be a permanent requirement for your cable line.

At Powertelcom, we produce the best spiral vibration dampers using the latest tech and automatic machinery. Our SVDs are made of weather-proof, non-corrosive material with a conduction-friendly spiral/helical design.

We have a wide array of SVDs suitable for different cable sizes and vibration frequencies. Each cable is color coded to make it easy for our customers to get the right one for their application.

Contact us today and get the best guidance on SVDs, SVD installation, and other electrical devices.