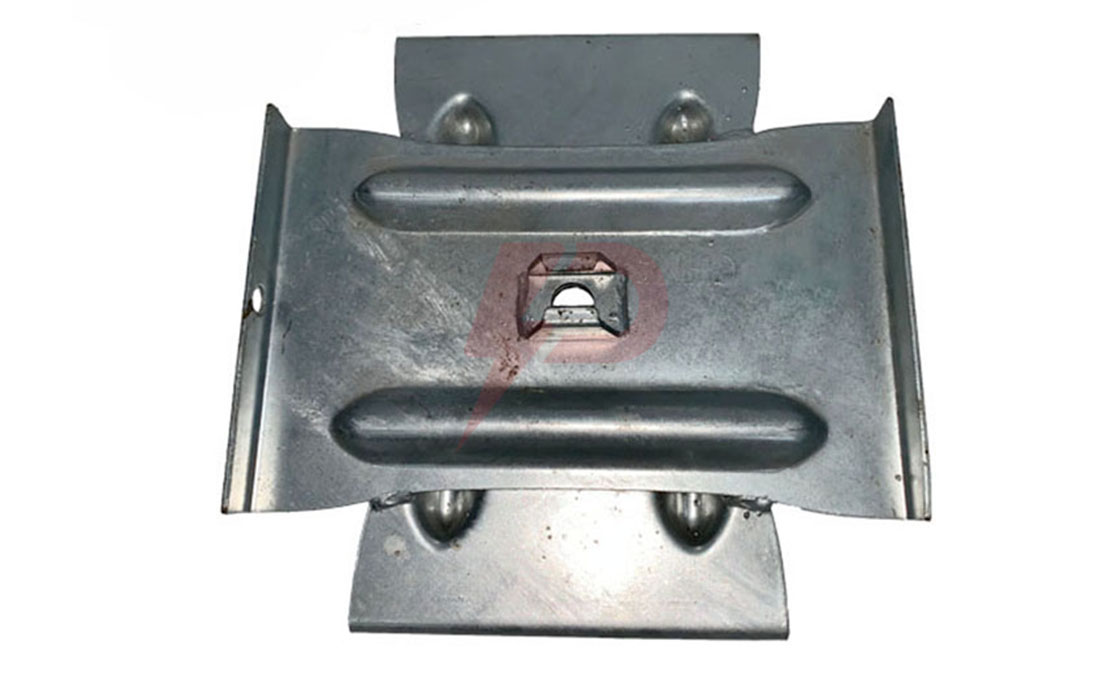

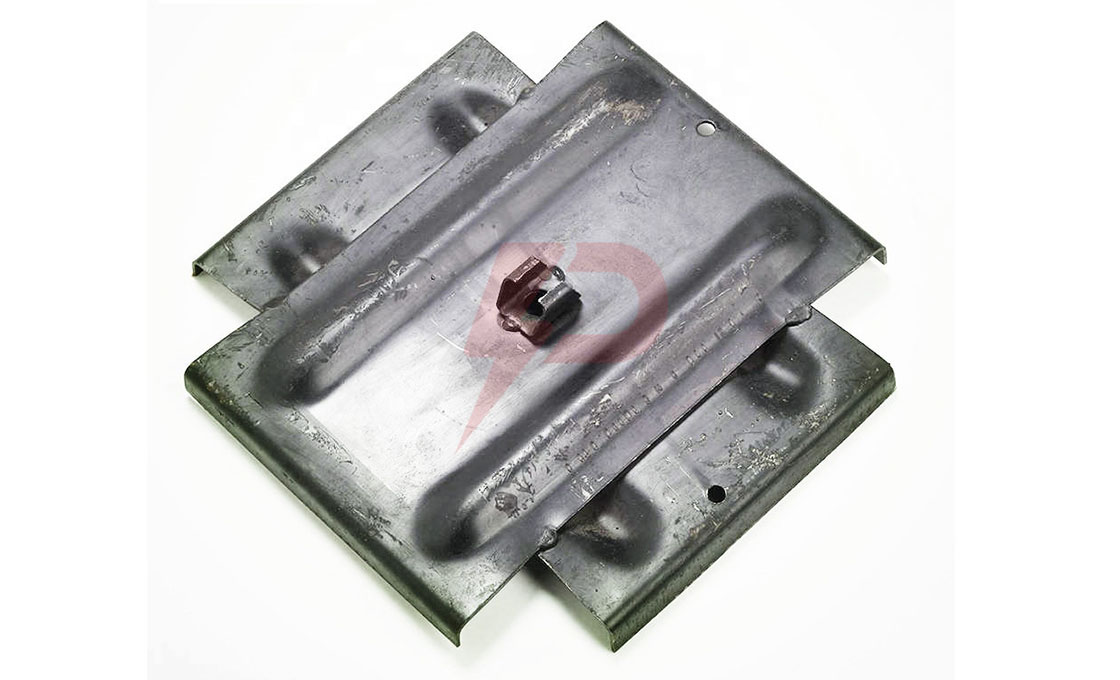

Cross Plate Anchor

The cross plate anchor is used to provide stability and support to several human-made and natural constructions. Also, making holes drilled by power diggers comes under an essential feature of cross plate anchors.

Formed up of two structural plates, these cross plate anchors are shaped for reinforcement to support and hold the nut from the forged eye rod; a retainer on the bottom of the anchor is available, which makes it easier to grip.

To install the cross plate anchor diagonally in the borehole, which is undercut, the anchor is placed at right angles to the guy.

Now there are two ways to cut a rod trench, either drilled by a small power auger or trenching tool. Also, both the rod trench and anchor must be refilled and compressed.

FEATURES

- These cross plate anchors are specialized in making holes augured by power drillers

- Made up of hot-dip galvanized steel with a built-in nut retainer, available in various lengths and diameters

- One-piece design with ridged plate rims and ribbed anchor plates

- These cross plate anchors are highly suitable for a range of soil classes with rust inhibitor-treated

Frequently asked questions (FAQ)

WHAT IS CROSS PLATE ANCHOR?

Large-bottomed earth anchors, the cross plate anchors are extended and used in many industries to provide a boost and structural support for mass constructions.

WHAT IS THE APPLICATION OF CROSS PLATE ANCHOR?

Where the size of the hole doesn't affect the holding capacity, the cross plate anchors drilled by power triggers are used, and these plates create connection points to the earth.

WHAT IS THE FUNCTION OF CROSS PLATE ANCHOR?

The main function of these cross plates anchors is that they are used in areas where the equipment needs to deploy screw anchors cannot have access easily.

HOW TO INSTALL CROSS PLATE ANCHOR?

By following these steps, we can easily install the cross plate anchor in a well-organized manner

- The first step is to prepare the anchor hole, which can be achieved by drilling the gap to the most profound depth

- The second step includes undercutting the hole, where adjusting the anchor plate at a 90-degree placement is the main objective

- Now digging the rod trench with a small auger or trenching tool

- Inserting the anchor by aligning the rod within 5 degrees of the guy

- The next step is tensioning and securing by balancing the nut retainer

- The last step is fixing the equipment in place by filling the hole in the vacant space.