Round Shaft Helical Anchor

A round shaft helical anchor is an extendable metallic system that is installed into the ground as a foundation to support above-grade structures.

Round shaft helical anchors have wider diameters. This distinctive feature gives them greater lateral strength and load capacity. This is the main reason why contractors prefer using them for a wide variety of compression applications. However, they are also suitable for some tension applications.

A round shaft helical anchor has three parts – a pilot point, lead, and helix (helical bearing plates). The helical bearing plates are welded onto the round shaft. Most round shaft helical anchors have two helical bearing plates. Although, some may have three or more.

A round shaft helical anchor provides support for an above-grade structure. They offer an economical and less soil-disturbing foundation for structures. Round shaft helical anchors are pushed deep into the ground. They help transfer the load of the supported structures to firmer soils in the ground.

These foundation systems are installed into the soils with the help of installation tooling, rotary equipment, and helical anchor extensions.

Key Features

- Galvanized steel round shaft

- Wider round shaft diameter

- One or multiple helical-bearing plates

- Diagonal sharp-edge pilot point

- Coupling hole on the lead point

- Good resistance to shear, compressive, and tensile loads

- Quick and easy installation

- Less disturbance to the soils

- Immediate loading is possible

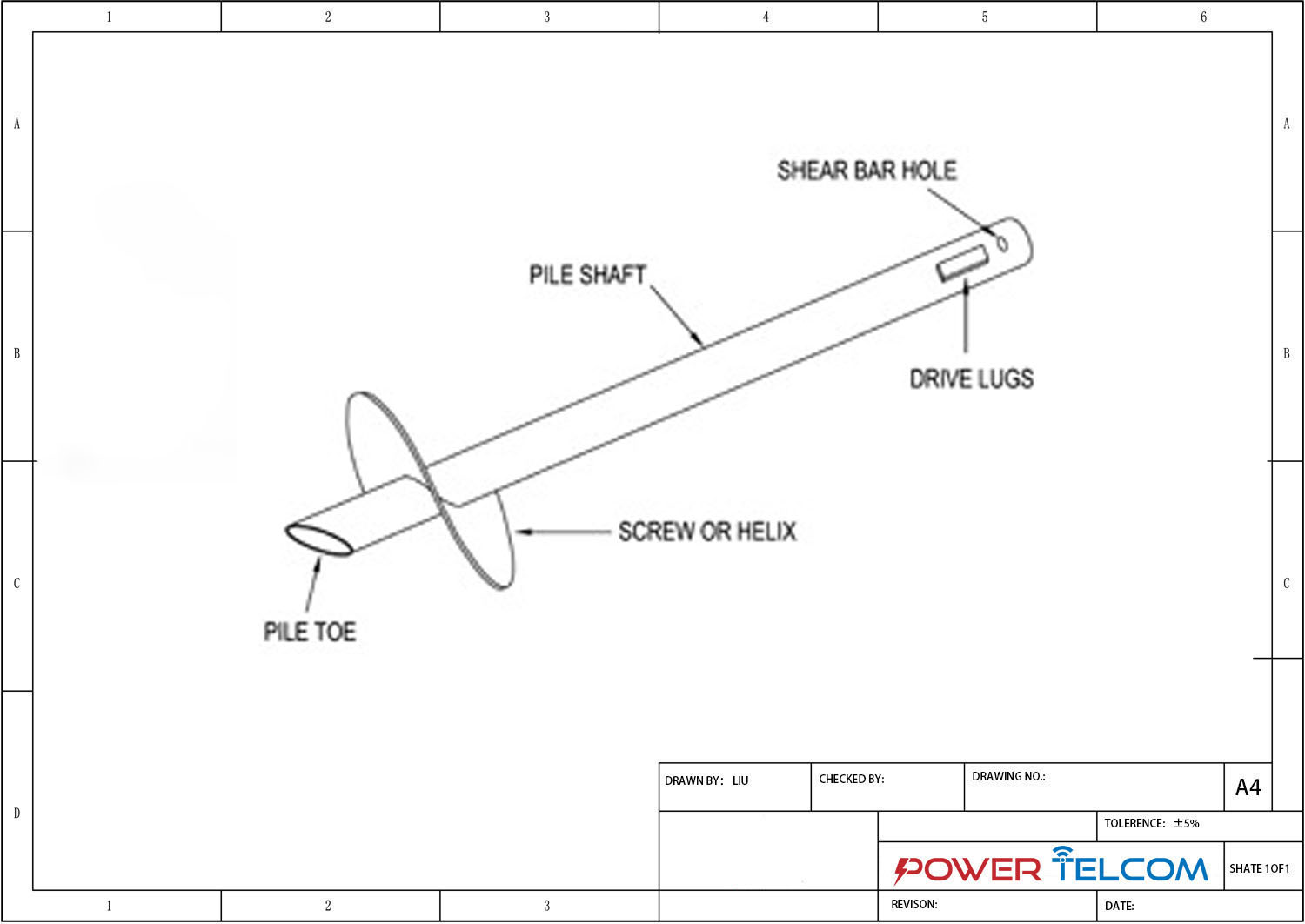

Round Shaft Helical Anchor Drawing

| Series | Plate Diameter-inches | Plate Area sq. ft. | Length | ||||

| “A” | “B” | “C” | |||||

| RHA84 | 10 | 12 | 14 | 2.07 | 84″ | ||

| RHA120 | 10* | 12* | 14* | 2.07 | 120″ | ||

Frequently Asked Questions (FAQs)

What is a Round Shaft Helical Anchor?

A round shaft helical anchor is a galvanized steel shaft used as a foundation in compression applications. Two or three helical plates are typically welded to the steel shaft. The helical plates hold firmly to stronger soils to provide support for the above-grade structure.

Key Applications of Round Shaft Helical Anchors

Round shaft helical anchors are designed to go deeper into the ground. So, they are anchored in the firmest soils to provide superior support for light and heavy loads. When properly anchored into the ground, these systems can effectively resist lateral and compression loading for a wide variety of applications. Key applications of these anchors include:

- Utility anchoring

- Lighting

- Commercial buildings

- Machine bases

- Docks, boardwalks, and bridges

- Mobile home foundation

- Roadway signage

Components of a Round Shaft Helical Anchor

A round shaft helical anchor consists of more than one component. Each component plays an important role in the design, installation, and working of the anchoring system. Here are the key parts of this anchoring system:

Lead

This is the main component of a round shaft helical anchor. It is the first portion of the anchor that’s driven into the soil. It is a galvanized steel shaft that can withstand humid conditions and resist corrosion. In addition, the upper part of the lead has a coupling hole for attaching a helical anchor extension.

Helix

This is a helical-bearing plate or helix-shaped flight. It is a crucial component of any round shaft helical anchor. It helps plough the soils as the anchor lead penetrates the earth. Helixes hold the anchor firmly in the soil. They also help channel the load of the supported structure to the surrounding soils. Round shaft helical anchors can have one helix or multiple helixes. Although, most of them have two or three helixes.

Pilot Point

This is the lowest portion of the anchor lead. It has a cross-sectional sharp edge that penetrates the ground first when the anchor is installed. The first helix is typically welded a few inches from the pilot point.

How to Install a Round Shaft Helical Anchor?

Round shaft helical anchors are pre-engineered for quick and easy installation. These anchors are mainly installed in soft soil conditions. The installation process requires a small team, which saves on labour costs. The team uses helical installation equipment and a wrench.

After site selection, the round shaft helical anchor is set up for installation. The anchor lead is inserted into the installation tooling of the rotary equipment. Then the contractor uses the equipment to drive the anchor lead into the ground.

The contractor will stop the rotary equipment when most of the lead section is in the ground. Then the equipment is pulled out. An extension is bolted to the anchor lead and the rotary equipment is attached to the coupling hole of the extension.

The contractor will resume the installation and drive the anchor until it is properly placed in firmer soils. The installation is successful and stopped when the required torque is achieved. The installed round shaft helical anchor is usually ready for loading immediately after the rotary equipment is pulled out.