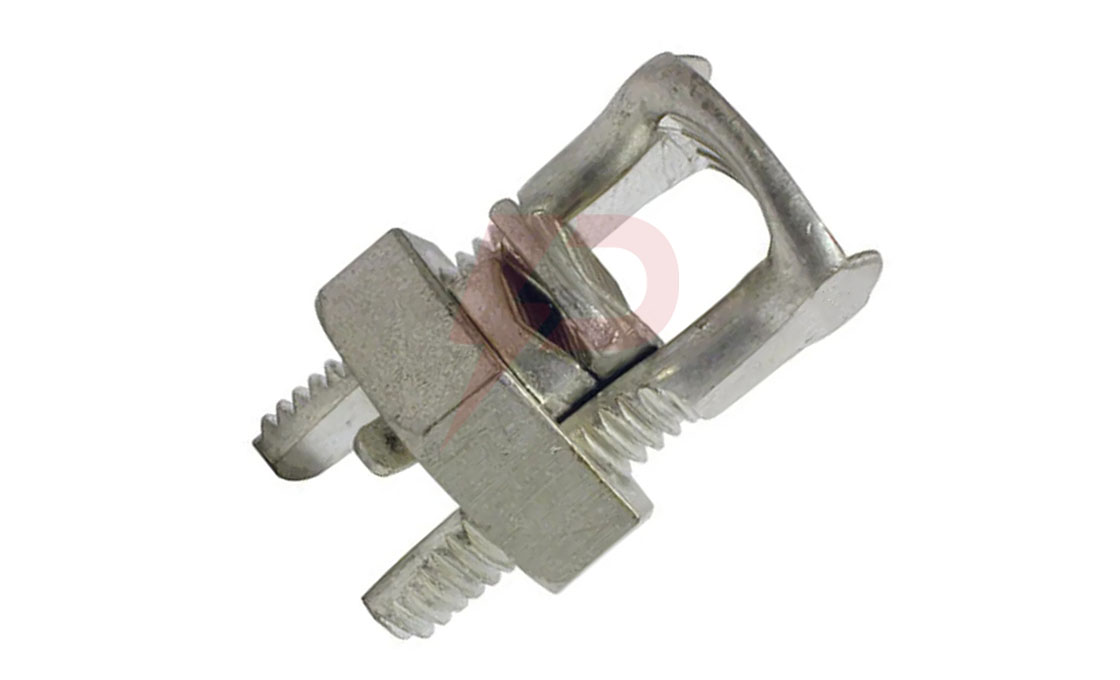

Split Bolt Connector

Split bolt connectors join and secure two or more electrical wires firmly, allowing electricity to move from one wire to another safely. They are also used in electrical connections requiring different cables of different sizes, making them versatile.

Split bolt connectors from Powertelcom are made from conductive materials like copper and aluminum. They are the best solution that offers a safe and reliable electrical connection. They save time and resources because their installation doesn’t need any unique tools.

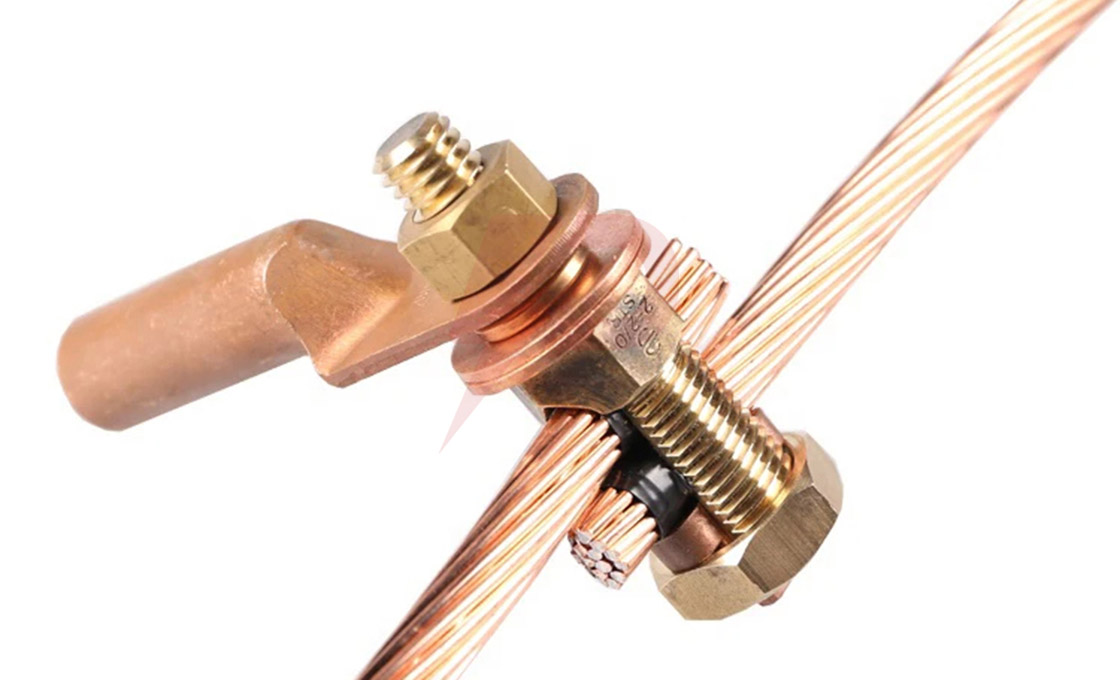

A split bolt connector has a body which is a short metal tube. This metal tube is split, forming a gap where wires are inserted. A screw runs through the body, and a nut tightens the screw. The pressure plate presses the wires once the screw is tightened.

Its open-ended screw and nut design makes it easy to inspect the wire connection visually, ensuring safety. The split gap where the wires are inserted allows the clamp to open and close. The flat plate works to evenly distribute the clamping force across the wires, tightly securing them.

A must-have accessory when using a split bolt connector is a wrench that fits the screw’s head to tighten or loosen the connection.

Key Features

- Easy and safe wire installation due to the split design

- Low electrical resistance connection

- Allows visual inspection of the connection

- Re-usable for other connections

- Accommodates a range of wire diameters

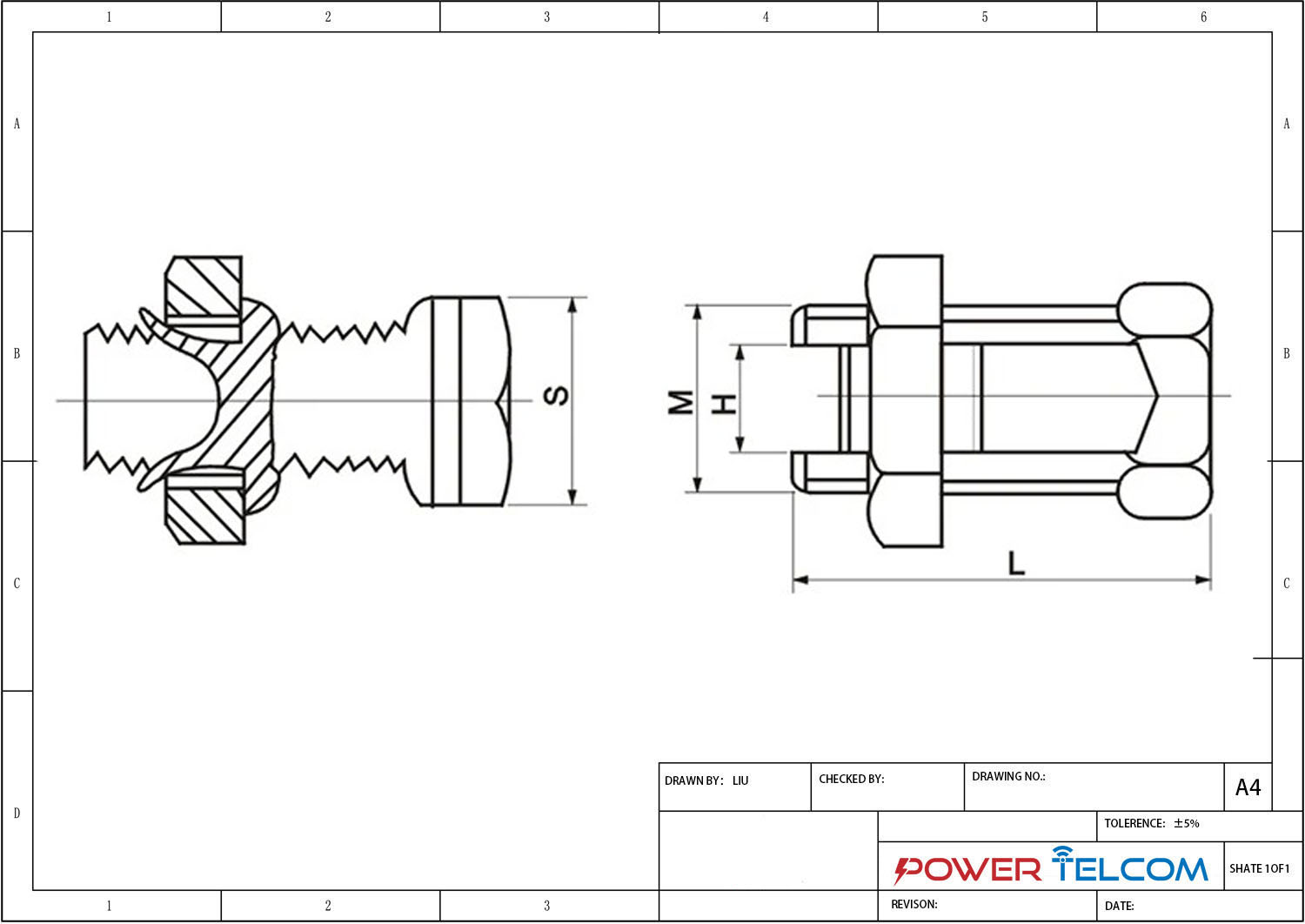

Split Bolt Connector Drawing

| Series | L | M | H | S |

| B/C-16 | 20 | M17×2.5 | 6 | 18 |

| B/C-25 | 27 | M19×2.5 | 7 | 20 |

| B/C-35 | 35 | M21×2.5 | 7 | 22 |

| B/C-50-70 | 42 | M23×2.5 | 11 | 24 |

| B/C-90-120 | 45 | M25×2.5 | 14 | 26 |

| B/C-150-185 | 60 | M29×2.5 | 17 | 30 |

| B/C-200-240 | 62,72 | M31×2.5 | 20 | 32 |

Frequently Asked Questions

What is a Split Bolt Connector?

A split bolt connector is a tool for connecting and fixing electrical wires and cables. It is mainly used in applications that need several wires for a stable connection.

The Split Bolt Connector Name

A split bolt connector has different names. Some call it the T-connector, and others call it a splicing connector. Its name arises from the device’s shape, as it has a bolt split at the centre.

Why Use a Split Bolt Connector?

Using a split bolt connector is advantageous because of its low electrical resistance connection. This simply means that electricity can move through the wires without any difficulty, minimizing overheating and issues happening due to energy loss.

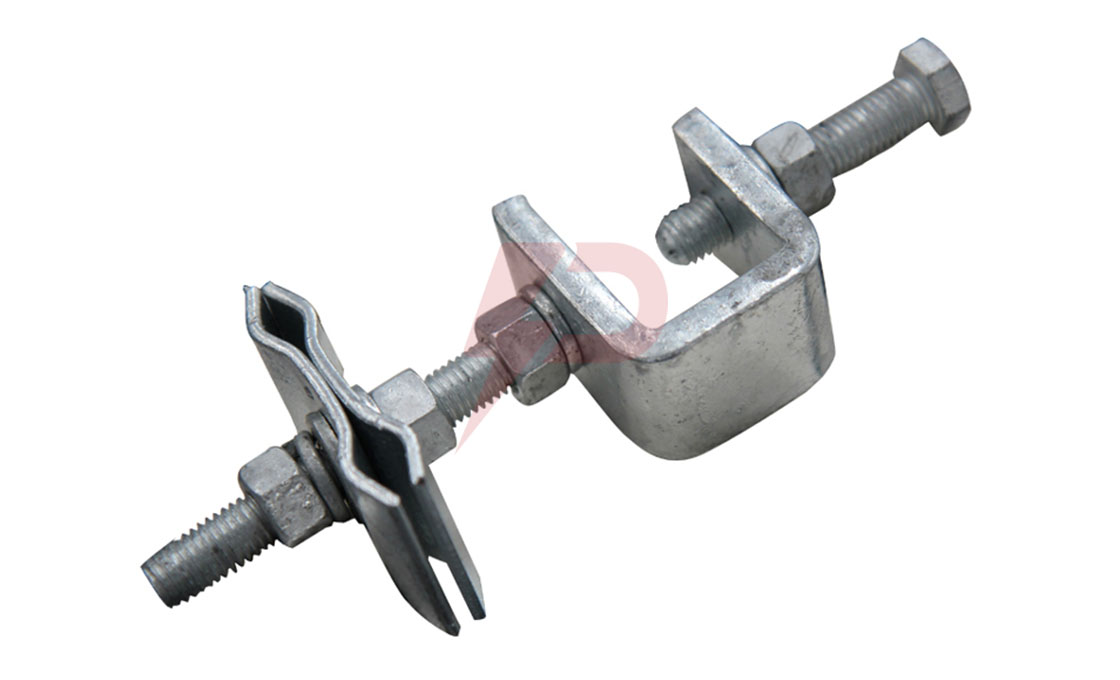

Split bolt connectors are also used in applications needing high electric current levels without damage. These applications include fencing, electrical grounding, and lightning protection systems.

Another advantage of split bolt connectors over other connectors is that they can be reused in different connections. Its screw mechanism allows the connector to be opened, wires removed, and then the device is reused in a different connection.

Split bolt connectors have different sizes and varieties that can be used in various situations.

Types of Split Bolt Connectors

There is a variety of split bolt connectors. This variety comes from the device’s design, the material the wire connector is used with, and whether it has an anti-seize compound. See examples below:

- Standard split bolt connectors: All-purpose wire connectors used in multiple applications

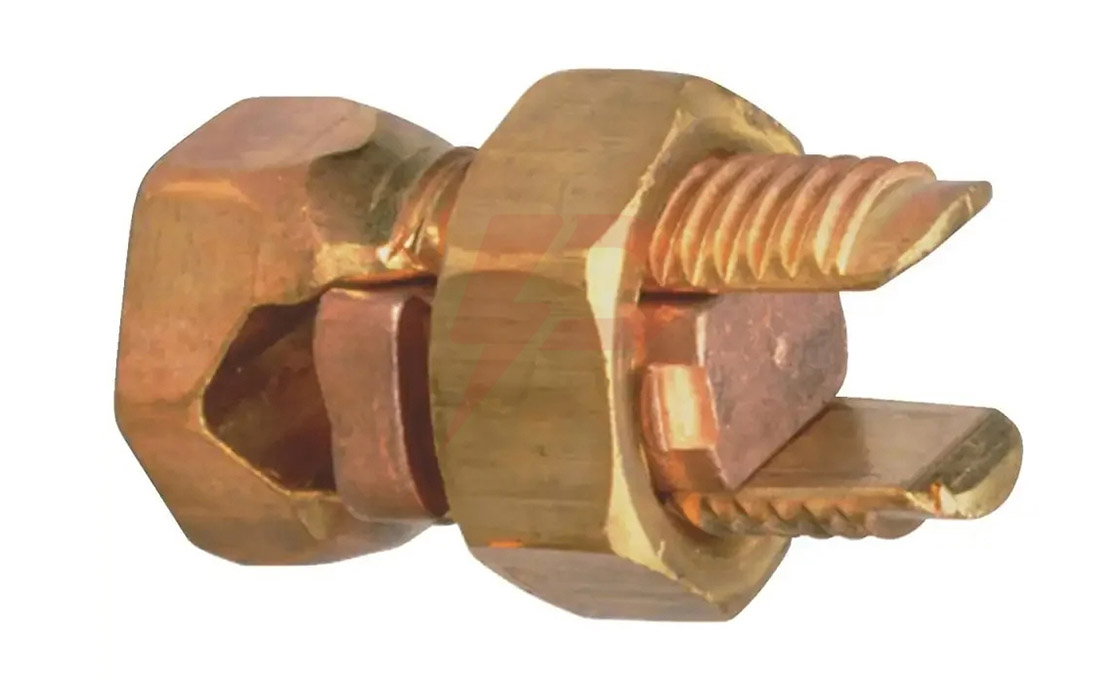

- Copper split bolt connectors: Made of copper, used when high electrical conductivity is needed

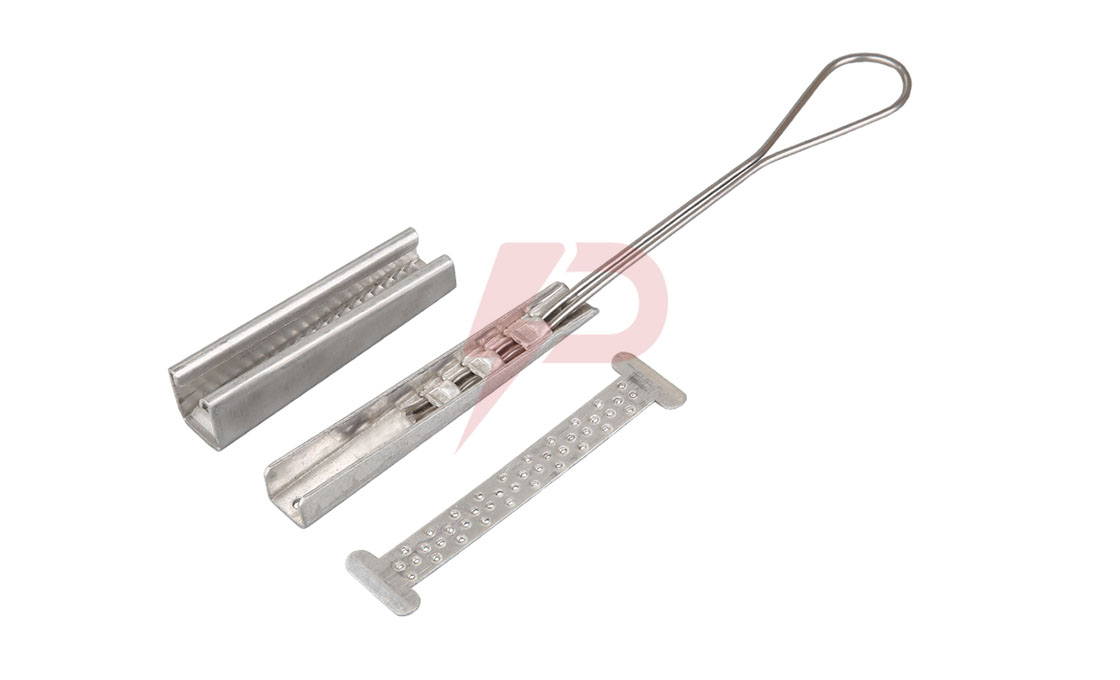

- Aluminium split bolt connectors: Made of aluminium and used in applications where weight is a concern, as aluminium is lightweight.

- Anti-seize split bolt connectors: Have a built-in compound to prevent corrosion.

How to Use Split Bolt Connectors

Even though split bolt connectors are used in different applications, using them is the same concept.

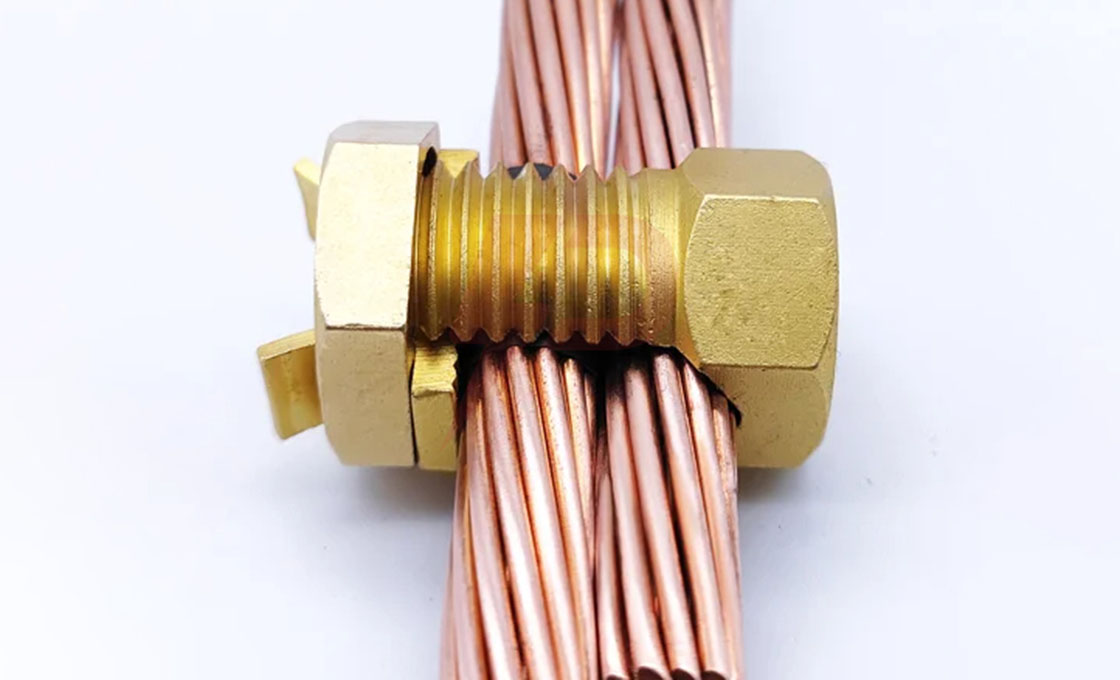

First, strip the insulation covering the wire ends to expose the conductive material whether you’re using an aluminium or copper split bolt connector.

Place the exposed wire ends inside the split in the bolt. Then, tighten the nut using a wrench by turning it clockwise. The nut has to be tight to avoid any heat loss when the applications are set. Go back with the wrench and keep tightening until the nut cannot move further.

The final step after tightening the connection is to cover the connection with electrical tape to shield and protect the connection points.

Factors to Consider When Choosing a Split Bolt Connector

- Always choose a split bolt connector made of a highly conductive material that resists corrosion.

- Choose the right size of split bolt connectors that are compatible with the wires being connected.

- Select a split bolt connector suitable for the application being done.