Electrical cross arms, also known as braces or traverses, are vital components of overhead transmission and distribution lines. They serve as support structures for insulators, conductors, and other electrical equipment, ensuring proper spacing and stability. This comprehensive guide will cover the different types, materials, and applications of electrical cross arms, as well as the factors to consider when choosing a wholesale supplier.

Table of Contents

Types of Electrical Cross Arms

There are several types of electrical cross arms, each designed to meet specific requirements of the power line system:

Straight Cross Arms

These are the most common type of cross arms, featuring a simple horizontal structure used for supporting insulators and conductors. They are widely used in both transmission and distribution lines.

V-shaped Cross Arms

Designed with a V-shaped structure, these cross arms provide better support for conductors, especially in areas with high wind loads or longer spans. They offer improved stability and reduced conductor vibration.

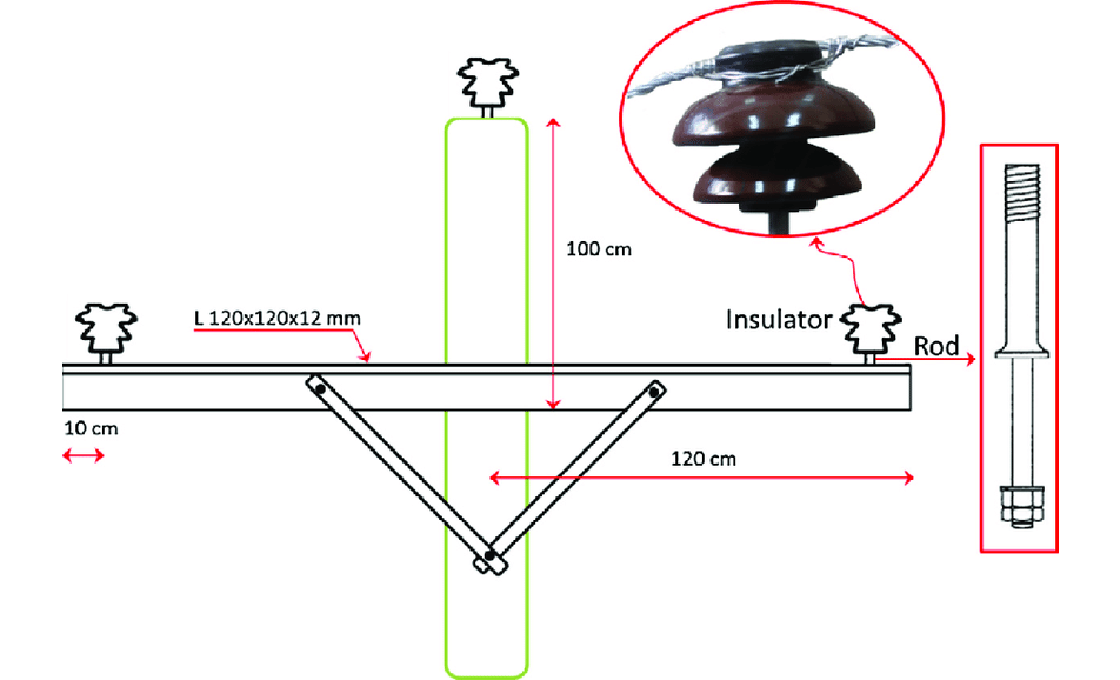

Horizontal V Cross Arms

These cross arms have a horizontal V shape, which offers increased mechanical strength and reduced wind resistance. They are commonly used in high-voltage transmission lines and substations.

Tangent Cross Arm

These cross arms are used in straight line sections of transmission and distribution lines. Tangent cross arms provide support for line conductors, ensuring proper spacing and maintaining stability.

Angle Cross Arms

Angle cross arms are designed to support conductors at the point where the line changes direction. They can be used in various configurations, depending on the angle of deviation.

Materials Used in Electrical Cross Arms

Different materials are used in the manufacturing of cross arms, each offering distinct advantages:

- Wood: Wooden cross arms have been in use for many years due to their low cost, easy availability, and ease of installation. However, they are prone to rot, insect damage, and require regular maintenance.

- Steel: Steel cross arms are highly durable, resistant to corrosion, and have a longer lifespan than wooden cross arms. They are commonly used in transmission lines and substations for their high mechanical strength and reliability.

- Galvanized Steel: Galvanized steel cross arms undergo a process of hot-dip galvanization, which provides a protective zinc coating to prevent corrosion. They offer excellent durability and long-lasting performance.

- Stainless Steel: Stainless steel cross arms are highly resistant to corrosion and have a longer lifespan than galvanized steel. They are used in areas with harsh environmental conditions, such as coastal regions.

- Composite Materials: Composite cross arms, made from materials like fiberglass-reinforced polymer (FRP), are gaining popularity due to their lightweight nature, high strength, and resistance to corrosion. They require minimal maintenance and offer a longer service life compared to wood and steel cross arms.

Comparison of Different Materials

| Material | Advantages | Disadvantages |

|---|---|---|

| Wooden Cross Arms | – Cost-effective – Easy to install – Suitable for low-voltage power distribution lines | – Susceptible to weathering and insect damage – Lower mechanical strength compared to other materials – Limited service life |

| Steel Cross Arms | – Highly durable – Resistant to corrosion – Ideal for high-voltage power transmission lines | – Heavier than other materials – Potential for corrosion if not properly maintained – Higher cost than wooden cross arms |

| Galvanized Steel Cross Arms | – Enhanced corrosion resistance – Highly durable – Suitable for various applications and environments | – Heavier than other materials – Higher cost compared to wooden cross arms |

| Composite Cross Arms | – Superior mechanical strength – Excellent insulation properties – Long service life – Suitable for high-voltage power transmission lines | – Higher initial cost compared to other materials – Limited availability in some regions |

Applications and Importance of Cross Arms

Electrical cross arms play a crucial role in the performance and stability of overhead transmission and distribution lines. Some key applications and benefits include:

- Supporting Insulators and Conductors: Cross arms ensure proper spacing between insulators and conductors, minimizing the risk of short-circuiting and maintaining the stability of the power line system.

- Withstanding Mechanical Loads: Cross arms are designed to withstand mechanical loads such as tension, compression, and bending forces caused by conductor weight, wind, and ice loading.

- Reducing Vibration: V-shaped and horizontal V cross arms help reduce conductor vibration, minimizing the risk of fatigue and potential damage to the power line system.

- Managing Line Angles: Angle cross arms facilitate changes in the direction of power lines, enabling efficient routing and reducing line stress.

- Enhancing System Reliability: Durable materials like steel and composite cross arms contribute to increased reliability and reduced maintenance requirements, ensuring uninterrupted power supply.

Choosing the Right Cross Arm Supplier

When selecting a wholesale supplier for electrical cross arms, consider the following factors to ensure you receive quality products and reliable service:

- Product Quality: Choose a supplier that uses high-quality materials and adheres to strict manufacturing standards to guarantee the durability and performance of their cross arms.

- Technical Expertise: A knowledgeable supplier with extensive experience in the industry can provide valuable insights and recommendations on selecting the right cross arms for your specific application.

- Customization: A supplier that offers customization options can cater to your unique requirements, providing tailored solutions to meet your specific needs.

- Pricing: Competitive pricing is important, but it should not come at the expense of quality. Look for a supplier that strikes a balance between cost and quality, ensuring you receive the best value for your investment.

- Lead Time: A reliable supplier should be able to provide accurate lead times and deliver your order on schedule. Timely delivery is crucial to avoid delays in your projects.

- Customer Support: Choose a supplier that offers excellent customer support, addressing your inquiries and concerns promptly and professionally.

Powertelcom: The Ideal Choice for Wholesale Cross Arms

In summary, electrical cross arms are essential components of overhead transmission and distribution lines, offering support and stability for insulators, conductors, and other electrical equipment. To ensure the best performance and longevity, it’s crucial to select the right type of cross arm and material for your specific application.

Powertelcom stands out as the ideal choice for your wholesale cross arm needs. With a strong commitment to quality, technical expertise, customization options, competitive pricing, and exceptional customer support, Powertelcom ensures you receive top-notch products and services to meet your requirements. Trust Powertelcom to be your reliable partner in the power transmission and distribution industry.

FAQs

What is the purpose of electrical cross arms in power lines?

Electrical cross arms provide support and stability for insulators, conductors, and other electrical equipment in overhead transmission and distribution lines. They ensure proper spacing between conductors and insulators, reduce conductor vibration, and withstand mechanical loads.

What materials are commonly used to make electrical cross arms?

Wood, steel (galvanized and stainless), and composite materials (such as a fiberglass-reinforced polymer) are commonly used in the manufacturing of electrical cross arms. Each material offers distinct advantages and is suitable for specific applications.

Why is it important to select the right type of cross arm for a specific application?

Choosing the appropriate type of cross arm ensures proper support, stability, and spacing for conductors and insulators in a power line system. It also helps manage mechanical loads, reduce conductor vibration, and accommodate line angles, all of which contribute to the overall performance and longevity of the power line.

What are the factors to consider when choosing a cross arm supplier?

Key factors to consider when choosing a cross arm supplier include product quality, technical expertise, customization options, pricing, lead time, and customer support.