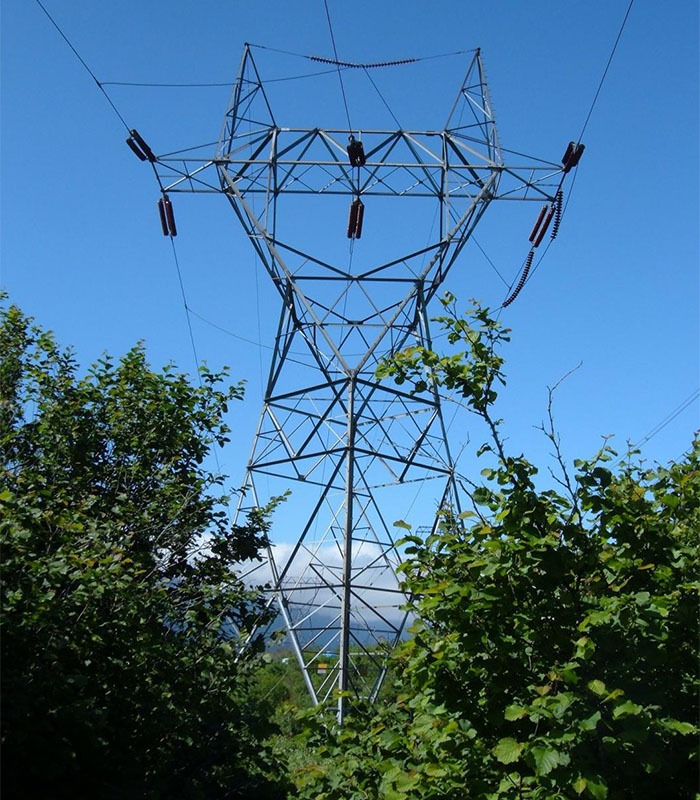

Overhead transmission in a rural area

Founded in 1954, Kenya Electricity Generating Company PLC (KenGen) is the leading power generation company in East Africa. It generates electricity through the development, management, and operation of power plants.

When it comes to transmitting electricity to rural areas, several resources are needed to accomplish such projects.

One thing about remote electrical transmission is the distance between poles is likely to be longer than what we usually see in urban areas. So, the powerlines need to be fully supported throughout the length. Otherwise, they will not be able to work effectively and efficiently.

If you are in charge of the rural o remote electrification projects, there are vital things that you should look at when buying the powerline fittings and accessories. Here are some of the aspects that you should consider.

Table of Contents

Materials and construction of the power line

Electricity in a rural area

The powerline fitting manufacturer should clearly state the kind or type of material that has been used for making a particular product.

If the cable is made of steel, the manufacturer should clearly state the type and grade of steel that has been used.

Given the harsh conditions that are expected in the rural electrification, the construction and material should be of premium quality to serve their purpose to the fullest.

If there are other additional protective features such as the coating and galvanization, the manufacturer should state them clearly.

Apart from just the material, you should try to know the construction features of the overhead pole line. For instance, if it is a stranded cable, you should figure out the number of strands that the cable has. Of course, this includes the arrangement and twisting of the wires.

As a buyer, you deserve to know the quality of the electrical line fitting that you want to buy.

Design and size of the fittings for rural electrification

Powerline cables and their fittings come in different designs, sizes, and specifications. Before you even pay for the fitting or accessory, confirm its specification.

It is vital because each design and size of the powerline accessory is directly associated with its specific area of application. You will buy a fitting that will fit perfectly into its respective field of application.

External conditions for the service

The powerline fittings for rural electrification won’t operate in a vacuum. It will be subjected to the environmental and climatic conditions of that place.

Some of these conditions include temperature, humidity, saline, and even altitude. Will the powerline fitting for rural electrification be able to not only survive but deliver the best performance under such conditions?

Once you are sure about this, then you can go ahead and buy it. Otherwise, keep exploring other options.

Are the electrical pole line fittings tested?

Rural electrification

How can you verify the quality and integrity of the electrical pole line accessories for rural electrification? It is quite simple. Just check whether the manufacturer has tested them.

Different types of tests are conducted on an electrical pole line. They include:

-Verification of the dimension test

-Tensile strength test

-Galvanizing test

-Elongation test

Apart from the tests, you should also confirm the certifications that are proof of the quality of the power line fitting. From these tests, you can be sure about the quality of the pole line cables and accessories.

In conclusion, rural electrification projects require maximum levels of seriousness, especially when it comes to selecting the relevant accessories. By taking these factors, you will end up buying the right power line fitting.