Electric Pole Accessories Export to Malaysia

overhead line accessory Manufacturer and Supplier

a reliable manufacturer

Are you finding a reliable manufacturer to supply overhead line accessories and electrical pole accessories to Malaysia? Do you know how to keep the pole line hardware high quality? Powertelcom is a good choice for you.

Powertelcom has supplied electrical pole accessories to Malaysia since 2010. We can fully do according to Malaysia’s design,inspection,packing requirement. And we have made all new molds for Malaysia’s market power fittings. We can send you the goods immediately if you are urgent. We know the Malaysia market, know the pole accessories, and know your needs.

Experience work with electrical supplier in Malaysia

The pole line hardware is mainly used to connect and support the overhead power lines and transmission lines.

Our QC team knows how to control the quality. All the pole line hardware is made according to the standard ISO1461, the finish is hot-dip galvanized.

Malaysia uses the pole line hardware include as below:

Clamp Concrete Pole 7.5m, clamp pole Hook clamp, Bridle Ring, Clamp Terminating Iron Pole, Bolt Eye, Stay Rod, Stay Plate, and so on.

You can click the images for more details.

Still not finding what you’re looking for?

Check product categories or contact us for more informations.

Product catecategory

Why choose us?

Powertelcom is located in China, started in 2001. We have become a manufacturer of choice for many industries for our product accuracy, timely delivery, professionalism, excellent product quality, product customization, and latest technology use.

Years of Experience

Supply Malaysia since 2010, kinds of Molds for Malaysia.

OEM & ODM are available.

High quality

Automatic machines for cutting and welding improve quality and reliability.

QC test control makes every manufacturing process going smoothly.

Effective Logistics Management

Big production capacity and on-time delivery make your project done on time.

Support free warehousing service

Some Products Specifications

Pole Band

The universal band is also called pole band or pole band clamp. A universal band is used to support and connect the stay wire to let the stay wire run through the spun pole. The Universal band material is carbon steel, the finish is hot-dip galvanized more than 86micron.

The construction for 7.5&9M POLE UNIVERSAL BAND

| UNIVERSAL BAND | Number of the part | |

| 1 | M12 Hexagon Nut | 2 no. |

| 2 | Flat heads bolt M12x50 | 2 no |

| 3 | Spring lock washerM16 | 2 no. |

| 4 | Hexagon Nut M16 | 2 no. |

| 5 | Cut Head square heckk bolt M16x95 | 2 no. |

| 6 | B-pole band | 2 no. |

| 7 | A-pole band | 2 no. |

| 8 | Thimble 5/8’’ | 1 no. |

Pole band packing:

The pole band is packed in a wooden box of 200 units each. On the outside of the wooden box, we will mark the manufacturer name, contract number, item name and quantity, Net weight, and gross weight.

UNIVERSAL BAND FOR SPUN 10M POLE

The UNIVERSAL BAND FOR SPUN 10M POLE is similar to the UNIVERSAL BAND FOR SPUN 7.5M POLE, just different in size and loading strength. The UNIVERSALBAND FOR SPUN 10M POLE is designed to clamp the stay assembly onto TNB approved spun concrete pole in HV overhead line system.

the construction for 10M POLE UNIVERSAL BAND

| UNIVERSAL BAND for 10M POLE | Number of the part | |

| 1 | M14 HDG Hexagon Nut | 2 no. |

| 2 | Flat heads bolt M14x50 | 2 no |

| 3 | Spring lock washerM16 | 2 no. |

| 4 | Spring lock washerM14 | 2 no. |

| 5 | Hexagon Nut M16 | 2 no. |

| 6 | Cut Head square heck bolt M16x165 | 2 no. |

| 7 | B-pole band | 2 no. |

| 8 | A-pole band | 2 no. |

| 9 | Thimble 5/8’’ | 2 |

If you want to know the drawing and price detail, pls contact us.

Street light bracket-long arm

Street light brackets have two different types: long arm and short arm.

The straight lighting bracket is used as an accessory in the street lighting lantern assembly. Street light bracket is also called street light arm or light pole bracket. The street light bracket consists of a bracket arm, supporting rod, removable sleeve, and a supporting plate.

There is a lot of welding work when making the street light arm. Powertelcom developed the automatic welding machine to finish the welding uniform and fast. The TNB asked for accurate sizes. The worker will measure the size per 50 units when producing them. To keep the finish bright and smooth, Jingyoung always does the second time selection to remove the burr and sharp edge.

1.Compare on welding condition at the plate.

The welding quality on the plate is fully welded type, not uneven welding.

2.Welding condition at the arm

The welding points at the arm are fully welded in the right direction. If the condition of the welding point found to be not fully welded, the workers will reject the street light arm onto a reject pallet.

3.Compare the appearance quality

The street light arms with burrs and sharp edges on the galvanized will be rejected. Jingyoung workers will grind smooth and re-paint the grinded area.

The short arm is used as an accessory in the street lighting lantern assembly.

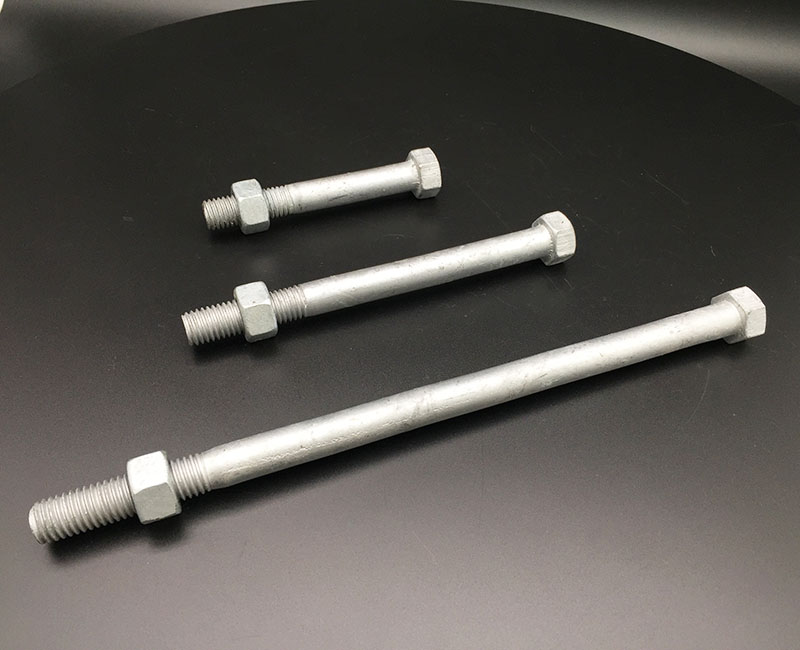

Hexagon head bolt and nut

Bolts and nuts are hot-dipped galvanized iron hexagon round head, size 300mmx16mm, 178mmx16mm, 114mmx16mm

SCHEDULE OF TECHNICAL PARTICULARS FOR BOLT & NUT 5/8X7”

| NO | Technical Speclfication | Requirements |

| 1 | Sample Required | Mandalory |

| 2 | Material | Mild Steel |

| 3 | Dimension | |

| a. Length of bolt | 178mm | |

| b. Length of thread | 50mm | |

| c. Thickness of hexagon round head | 12mm | |

| d. Thickness of nut | 15mm | |

| e. Width of bolt head & nut | 25mm | |

| F. Diameter of hole | 16mm | |

| 4 | Tolerance | 1% |

| 5 | The test results in accordance with standard | BS EN ISO 1429 |

HV Dead End Double Clamp Bracket

HV Dead End Double Clamp Bracket is designed to be used in the TNB MV ABC distribution system.

Which kind of poles are these HV Dead end double clamp used on?

- To anchor two HV dead-end clamps on 10m-19-5kkn span concrete distribution or section poles

- To anchor two HV dead-end clamps on 10m-19-5kn span concrete terminal poles

- To anchor two HV dead-end clamps on 10m-19-5kn angle poles

What’s the HV Dead end double clamp breaking load?

It is capable of withstanding a minimum breaking load of 62kn for 1 minute or 31kn per circuit for 1 minute.

The construction of the HV Dead end double clamp.

The bracket includes

1)two units of C-Channel iron

2)two units of M16 U-bolts,

3)four nuts complete with washer for the M16 U-bolt,

4)two 5/8 inch x 13inch studs complete with nuts and washers,

5)two units of 5/8 bolts and nuts complete with washer.

Why customers choose Powertelcom HV Dead end double clamp?

Our products are free from sharp edges, burrs, flash, or surface projections which could cause damage to the MV ABC or inflict injury to the installer or user

If you want to know the detailed drawing, pls contact us now.

Triangular bracket for HV ABC

The triangular bracket is designed to hang one MV insulated suspension clamp on 10m-19-5kn spun concrete poles. The Triangular bracket is used as an accessory for MV ABC System. The triangular bracket required to withstand a minimum breaking load of 30kn per the 60s during testing.

The triangular bracket is designed to hang one MV insulated suspension clamp on 10m-19-5kn spun concrete poles. The Triangular bracket is used as an accessory for MV ABC System. The triangular bracket required to withstand a minimum breaking load of 30kn per the 60s during testing.

The construction for the Triangular bracket

| Triangular bracket | Number of the part | |

| 1 | C channel iron | 1 no. |

| 2 | Mild steel bar attached to the main C channel iron | 2 no |

| 3 | M12 Bolts and nuts | 4 no. |

| 4 | M16 U-bolt with 4no. M16nuts and washers. | 1 set |

| 5 | 5/8 inch x11 inch studs | 2 no. |

| 6 | 5/8 inch buts | 4 no. |

ABC SUSPENSION HOOK

ABC SUSPENSION HOOK is also called J hook or universal hook. Universal hook is used to hang or suspend aerial bundle cable accessories such as suspension clamp.

Stay Bow with Thimble

The stay bow with the thimble is used in the High Voltage Aerial Bundle Cable (HV ABC) Distribution System. The mild steel galvanized stay bow & thimble is designed for use as an accessory for HV ABC stay wire installations suitable for 2500mm x19mm stay rod and up to Grade 700 SWG 7/8 stay wire. The mild steel galvanized stay bow and stay thimble is required to withstand a minimum breaking load of 62kn.

D bracket

D bracket is made from 38x6mm thickness mild steel flat with hole diameter 175mm for 16mm diameter bolts The D bracket is hot dip galvanized according to BS729

Stay rod and stay plate

Stay rod is made by hot forged. Jinyong amends the mold after finish every 300pcs stay tod to make the square head size accurate. There are rod diameters of 12mm, 16mm,18mm,20mm, and 22mm. Powertelcom can develop new sizes according to customers drawing. The stay plate middle square hole is fit for the stay rod square head. The stay plate is used together with the stay rod to stop the stay rod from moving. The stay plate is under the ground to act as the base supporting plate.

Frequently asked questions (FAQ)

For the different types of pole line hardware, there are different ways to do the hot-dip galvanization. For the electrical cross arm, alley arm, the manufacturer does the hot-dip galvanization at a big bow, the liquid temperature was controlled very well. And the consist element was settled according to a certain percent. For the casting part like socket clevis and pole top bracket, there is a different element consist to do the hot-dip galvanization. There are a few kinds of hot-dip galvanization testing standard for the overhead line fitting. For the Asia market, like Malaysia and Indonesia, they test the hot-dip galvanization according to ISO1461. For South America, they test the hot-dip galvanization according to ASTM123. The manufacturer usually charges the tooling, if you don’t accept our present power fitting type. The manufacturer will make new tooling based on your design, and the new tooling belongs to you. The manufacturer just helps you to take care of the tooling in our factory. If you have paid for it, the manufacturer can also refund you the tooling cost if you ordered a certain quantity. Yes, of course. It’s a necessary step to confirm the sample before mass production. If the type of pole line hardware you required is in stock, the customer will only burden the express cost and have the sample for free. If you need to make new samples according to your drawing, you should charge the sample cost. Only T/T and L/C are acceptable, OA is not. If the pole line hardware you required is in stock, the goods will be shipped immediately after you pay. If there is no stock for your required, 20 days are needed to make 1*20 containers and confirm further whether it is needed to make new tooling for it.How to make hot-dip galvanization perfect?

What is the hot-dip galvanization test standard?

Who will charge if making a new design?

Can we get a sample before placing an order?

What’s the payment item?

What is the delivery time for the power fitting?