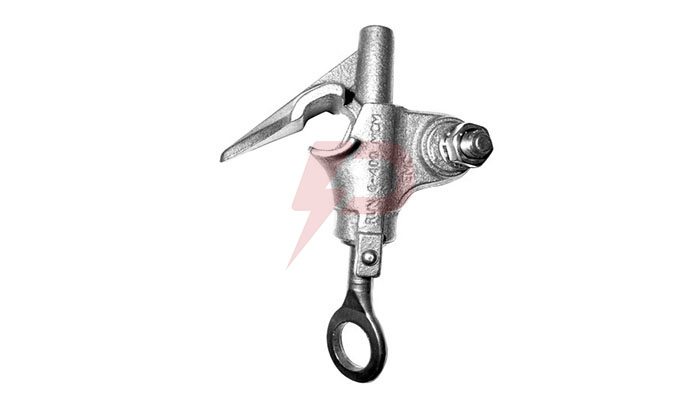

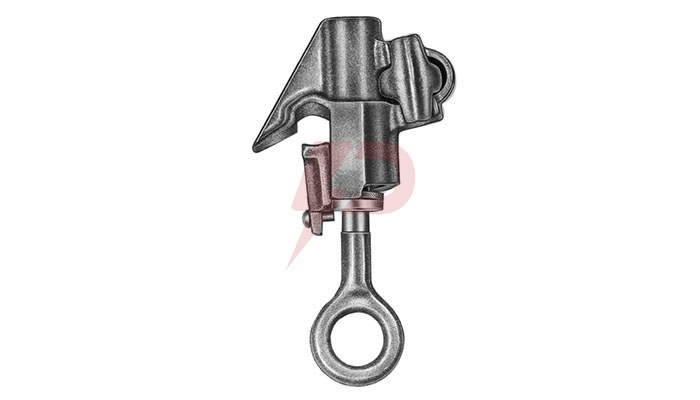

Hot Line Clamp

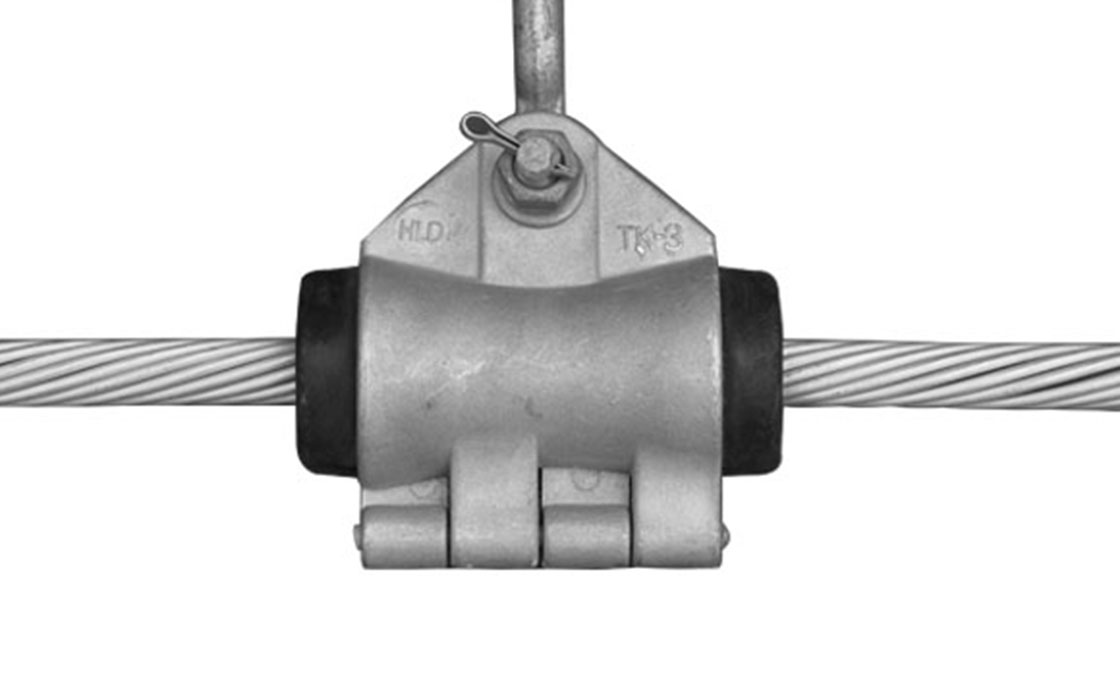

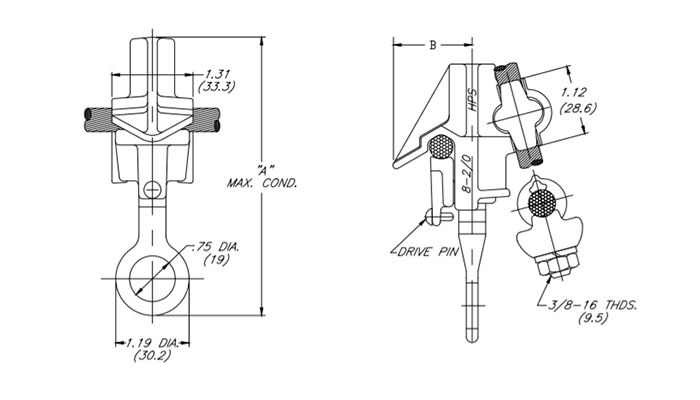

The hot line clamp is a metal structure that insulates current from high voltage transmission lines to the transformer. The aluminium body works either as a permanent or temporary fixture to connect conductors by using the keeper and eyebolt to secure and maintain a constant pressure as a reliable fixture to attach to hotlines.

As an industrial product made of high strength steel, the clamp structure can withstand the high voltage from the transmission lines, extreme temperatures, and direct contact with the high-voltage current.

The hot line clamp tap is specially designed for distribution tap connections and provides good corrosion resistance, it also can be adjusted and efficiently lower the variation of insulation resistance.

If you’re a utility worker or job site electrician, no matter whether you work in-line or on-tower, the Hot Line Clamp has been designed specifically to meet your needs as they’re used in almost every electrical distribution system.

Features

- High Strength & Light Weight

- Corrosion Resistant

- Conductor Compatibility

- Versatile jaw width

- Reduced joint temperature

- Minimal conductor cold flow

The Hot Line Clamp is compatible with all distribution tap connections such as Copper, Aluminium, and ACSR conductors.

Frequently asked questions (FAQ)

What is a Hot Line Clamp?

A Hot Line Clamp is a metal fixture that is used to connect a Hot Line and a Transformer. Electricians commonly use it for line tap distribution connections as an attachment.

What is the application of a Hot Line Clamp?

The Hot Line Tap Clamp is a portable, heavy-duty clamp that is used for all hot line tap connections and full duty connections involving major line equipment.

Components of a Hot Line Clamp

- Body and Keeper

- Eyebolt

- Eyestem

- Spring on eyestem

How to install a Hot Line Clamp?

- Make the tap conductor straight and inlay

- Wire brush the tap conductor using a conductor cleaning brush to remove debris and oxides

- Loosen the tap eyebolt to insert the tap conductor

- Insert the tap conductor through the eyebolt and tighten per torque instructions

- If installing to the central conductor, clean the conductor thoroughly with the conductor cleaning brush.

- Install the eyestem into the hook of the universal grip tool

- Hook the tap clamp onto the main conductor or stirrup

- Apply some tension to the conductor to tighten to the recommended torque value