Guy Grip

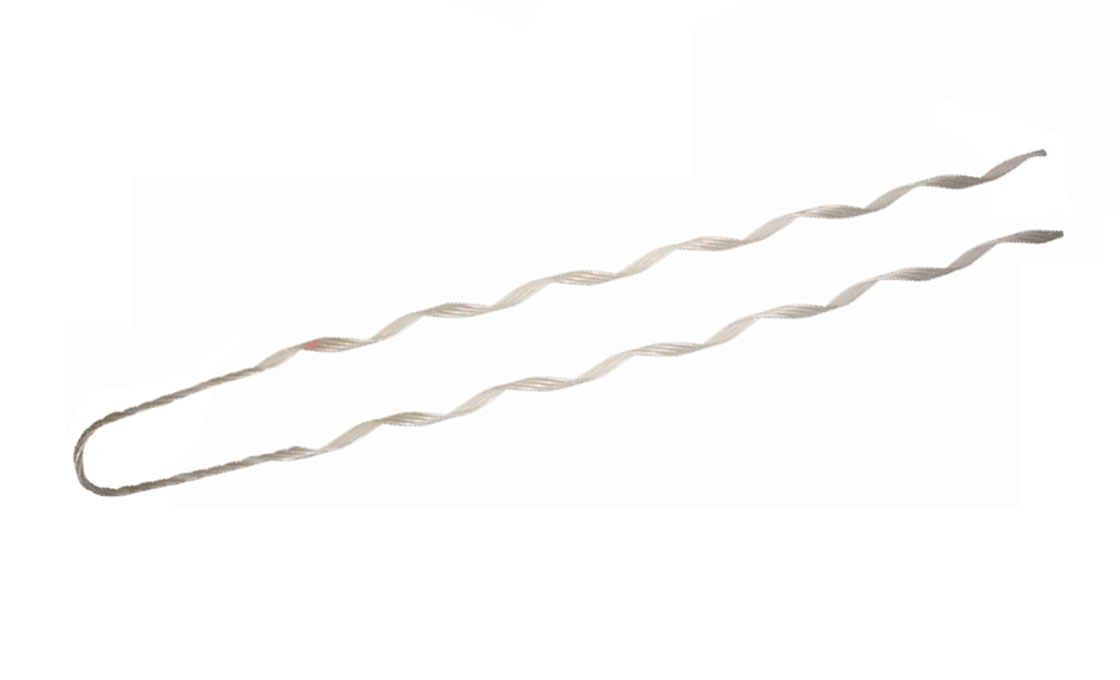

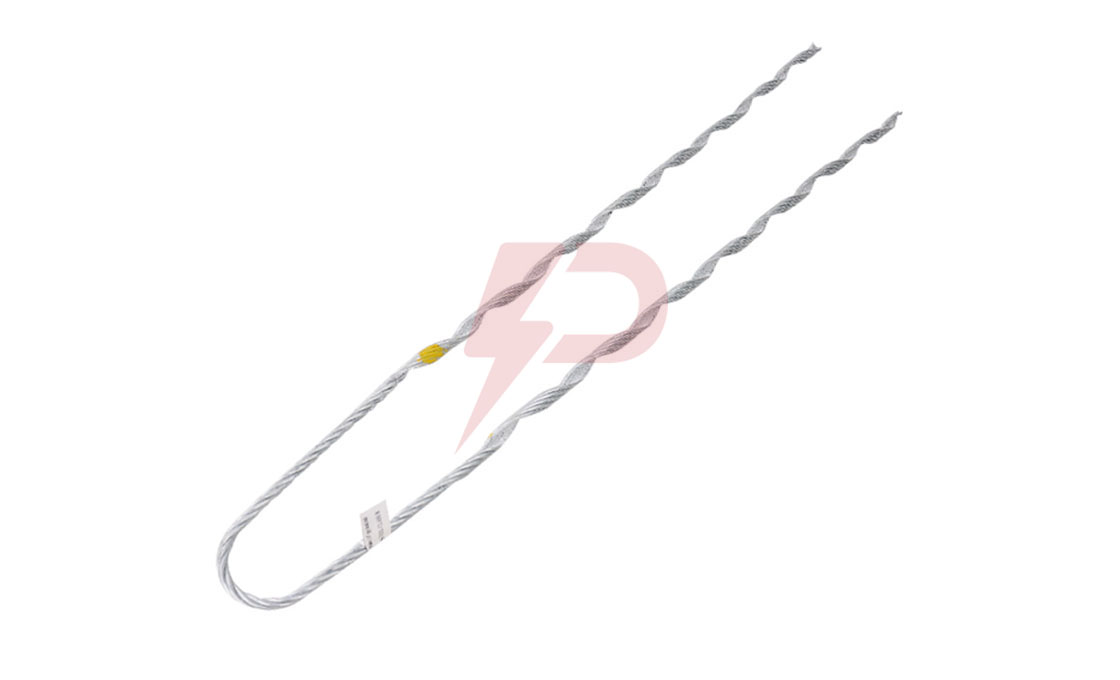

A guy grip is also known as the guy grip dead end or a preformed guy grip. The recognized and reliable preformed guy grip dead end for the connection is also responsible to grip the conductor, ground the wire, and application for optical fiber.

The components are added to the equipment according to the needs of the dead grip. The guy grip has legs in the form of a helical having unreactive grits with each turn holding the messenger wire. In addition to that, the strand has the tacking up and is regarding the guy grip. It is available in a multitude of sizes.

When it is wrapped over the conductor or a product, let’s say stay wire, the grip strength will b strong for avoiding the slip happening among the guy grip and conductors.

Most of the raw materials used in the making of a guy grip include aluminum, galvanized finish. We believe in a perfectly executed grip performance, needs of the customers and others. Do contact us for asking any queries pertaining to the article.

We pay attention to the words and concern of every client and bring out the best in our performance to exceed the expectations of our client.

1)Corrosion Resistant

- The preformed grip is hot-dip galvanized as per BS EN 10244 –2:2001.

- Weight of coating and uniformity of coating tests shall be made as per

BS EN 10244 – 2:2001

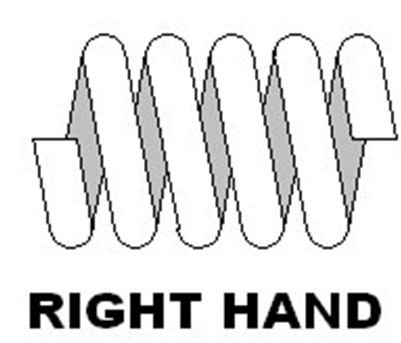

2)Right Hand Lay

The preformed grip is made for right-hand lay strand.

3) Mechanical Test

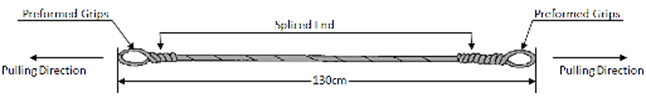

- The preformed grips are wrapped around the single or stranded

galvanized steel wires and pulled as indicated in Figure 1 below

shall be as follows:

b)The preformed grips are with good quality to avoid unwinding itself during the test.

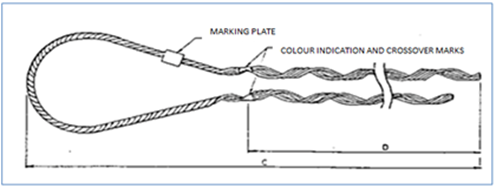

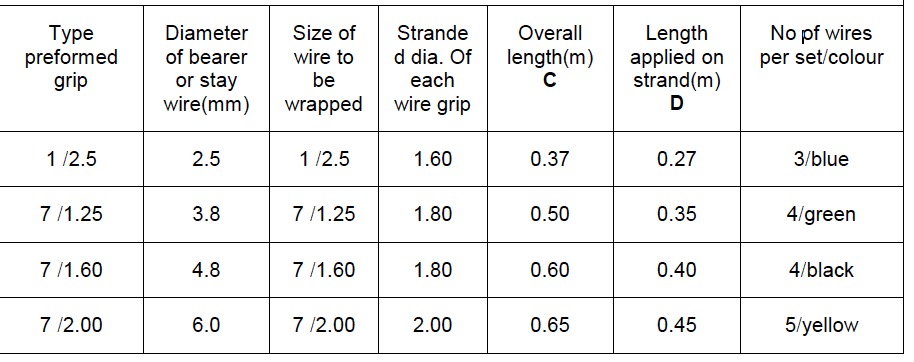

4) Dimension Test

a. All wires are chamfered at the ends

b. Starting or crossover points are indicated with paint. The color of the paint identifies the size and the contact length of the preformed grips. The preformed grip for 1/2.5 guy wire is marked as blue. The overall length is 370mm. The preformed grip for 7/2.5 guy wire is marked as green. The overall length is 500mm. The widely used preformed grip type is for 7/1.6mm. The mark color is black, there are 4 wires to consist the guy grip.

c. To facilitate removal, one leg of the set is designed longer than the other.

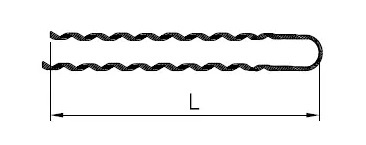

| Cat.No. | Applicable Conductor | Dimensions(mm) | Matching gold | Weight(kg) |

| L | ||||

| NL-70-70/10 | JL/G1A-50/8 | 670 | QXH-0748 | 0.2 |

| NL-70-50/9 | JL/G1A-70/10 | 720 | QXH-0748 | 0.2 |

| NL-70-95/15 | JL/G1A-95/15 | 860 | QXH-0748 | 0.6 |

| NL-70-95/20 | JL/G1A-95/20 | 860 | QXH-0748 | 0.6 |

| NL-70-120/20 | JL/G1A-120/20 | 870 | QXH-0748 | 0.8 |

| NL-70-150/20 | JL/G1A-150/20 | 1000 | QXH-0748 | 1.1 |

| NL-70-150/25 | JL/G1A-150/25 | 1000 | QXH-0748 | 1.1 |

| NL-70-185/25 | JL/G1A-185/25 | 1140 | QXH-0748 | 1.7 |

| NL-70-185/30 | JL/G1A-185/30 | 1140 | QXH-0748 | 1.7 |

| NL-70-240/30 | JL/G1A-240/30 | 1250 | QXH-0748 | 2.3 |

| NL-70-240/40 | JL/G1A-240/40 | 1250 | QXH-0748 | 2.3 |

| NL-70-300/25 | JL/G1A-300/25 | 1820 | QXH-0748 | 3 |

| NL-70-300/40 | JL/G1A-300/40 | 1820 | QXH-0748 | 3 |

| NL-100-185/25 | JL/G1A-185/25 | 1140 | QXH-1048 | 1.7 |

| NL-100-185/30 | JL/G1A-185/30 | 1140 | QXH-1048 | 1.7 |

| NL-100-2405/30 | JL/G1A-240/30 | 1250 | QXH-1048 | 2.3 |

| NL-100-240/40 | JL/G1A-240/40 | 1250 | QXH-1048 | 2.3 |

| NL-120-240/40 | JL/G1A-240/40 | 1250 | QXH-1248 | 2.3 |

| NL-120-200/25 | JL/G1A-300/25 | 1820 | QXH-1248 | 3.8 |

| NL-120-300/40 | JL/G1A-300/40 | 1820 | QXH-1248 | 3.8 |

Guy Grip/Dead End Grip Buying Guide

There are different types of accessories that can be used for power and telecommunication pole lines. Most of them are usually used for completing different forms of connections.

One of the accessories is the guy grip which is also referred to us the dead-end grip. I will also guide you on how to buy the best guy grip in China.

- What is a guy grip?

- Types of guy grips

- Uses of guy grips

- What is the key specification of dead-end grips?

- How to install the guy grip dead end?

- Buying a Dead-end Grip in China

What is a Guy Grip?

A guy grip is also named dead end grip, it is a piece of pole line hardware that is used for creating a connection to the eye thimbles.

These thimbles are usually found on the power and telecommunication poles.

The ergonomic design of the dead-end grips allows them to be connected to the aerial, among other types of guy structures.

This grip is also designed to protect the conductor cable from distortion.

Most dead-end grips in the market are made of metallic strands. Such types of materials are capable of resisting wear and other forces that are capable of causing physical and structural damages.

What are the Types of Dead-End Grips?

There exist different types of dead-end grips in the market. Since these accessories are used for different applications and diverse environment, it is impossible to come up with one universal accessory

Let’s have a brief overview of the types of dead-end grips:

Guy wire dead They are common for guying poles which are used in the construction, power, and telecommunication industries.

They work with strands that have a 1-inch diameter or lesser than this value.

The presence of off-set tips on this guy grips enhances its ease of installation. This is an addition to the color codes that are attached to their ends.

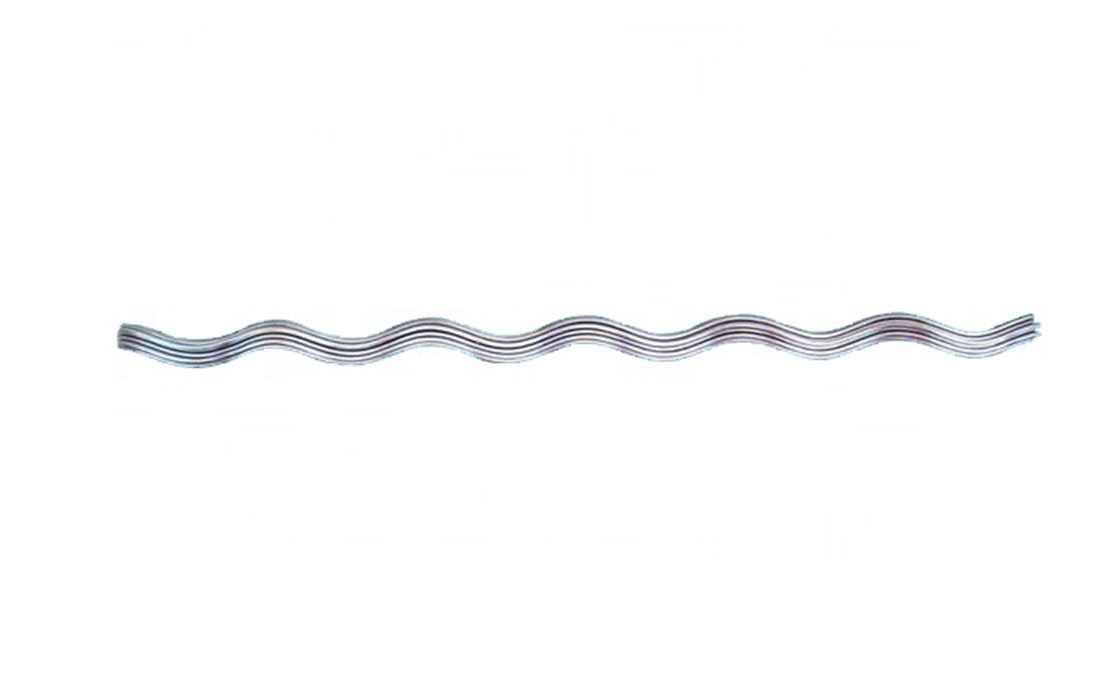

Preformed grips

You can also choose to buy preformed grips in China.

This one has similar material to one of the conductors.

It is characterized by high tensile strength and resistance to corrosion.

Why Should I Buy Guy Dead-End Grip?

Guy grips are known for creating the best connections in whichever areas of applications that they are put into.

They have become popular to the extent that they are replacing the once-popular NX tension clamps.

Guy clamps are used for completing connections in the transmission lines, telecom lines, and other utilities that depend on the pole lines for support.

The versatility of guy grips is another reason behind their immense popularity. They can work with different types of cables including AAC, ACSR, and AAC cables.

Tight grips. Resistance to corrosion, ease of installation, and the ability to sustain electric current air just some of the reasons that make dead-end cable grips reliable.

The high breaking load of guy grips enables them to sustain heavy cables.

Before being used, guy grips are subjected through hot-dip galvanization and electroplating. These processes protect the cables from rust and other chemical-induced damages.

What is the Key Specification of Dead-end Grips?

Guy grips are not all the same. They come in specifications. Before you buy these powerline accessories, you should be familiar with these features.

Here are the key specifications of guy wire dead-end grips:

-Dead-end grip dimensions: The dimensions of guy grips are defined by diameter and length. The choice of length and diameter that you choose will depend on where you want to use the accessory.

Also, the dimension can be uniform or vary throughout the grip dead-end depending on the design.

-Guy grip dead-end material: Guy grips are made of different material types. The most common materials include aluminum and galvanized steel and aluminum-clad steel wire.

Each material type has its unique properties. Some materials are stronger than others.

Which material should type of guy grip should I choose? It all depends on your needs and the uses of the guy grip.

-Guy grip design: There are slight variations of guy grip designs. The most popular design is the dead-end grip that has a single hole at its end. Once you bend this preformed grip, it will create two hols through which the conductors will pass.

-Guy grip finish(hot-dip galvanization): When buying guy grips in China, it is critical to take care of the finishing.

Ensure that the dead-end grip has been subjected through hot-dip galvanization. This way, it will have maximum protection against corrosive elements and gents of rust.

–Dead-end grips tensile strength: How strong is a dead-end grip? The strength is usually determined by the tensile strength of the material.

This parameter ensures that the guy grip does not break under heavy load.

Not sure of the above grip guy specifications? Seek help from experts. They will give you every information that entails choosing the best guy wire grip.

How to Install the Guy grip Dead End?

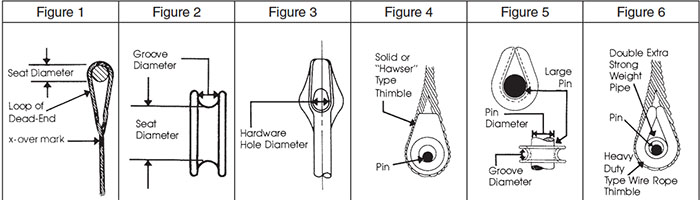

Installation methods on different guy grip hardware accessories

After buying a guy wire grip, the next phase is installation. The good news is dead end grip installation is not as complicated as some people assume.

A few touches here and there and you will be doe with the stay wire installation of a guy grip.

Start by passing dead-end guy grip through the thimble. This is if you want to connect.

Ensure that your connection extends to the area that has a bend.

From there, proceed to install the subject conductor along the strands of the guy grip. Ensure that the conductor fits perfectly on the strands of the grip.

Fit the conductor to the end of the guy grip then cover the strands using the opposite side of the guy grip so that they overlap each other.

As you can see, you won’t need to be an expert to do the installation. However, you may need an extra hand to assist you.

The video below illustrates a dead end grip installation:

Buying a Dead-end Grip in China

Planning to buy guy grip China? The process is quite easy. You can choose to buy dead-end grip online from the comfort of your home.

Before you do that, ensure that you buy from the best dead-end grip manufacturers in China.

This is the surest way to end up with the right products.

This is why we at Powertelcom pride in manufacturing and supplying quality guy grips.

Simply contact us to find more information including the prices of dead-end grips.

FAQ

What is a guy grip?

A guy grip is also known as guy grip dead end, preformed guy grip or dead-end cable grip. The preformed guy grip dead end is a product for the connection responsible to grip the conductor ground the wire, and application for optical fiber.

Some terminology of guy grip

- Identification Tape: Indicate catalog number, nominal sizes.

- Cabled Loop: Furnished as standard, all sizes

- Cross-over Marks: shows the starting point for the application.

- Color Code and Length: shows strand size

- Short Leg-Long Leg: Indicates rods belonging to each leg. When an application, the short leg should be applied first.

What fittings are usually used with guy grip?

Acceptable fittings for guy grips:

- Anchor rods

- Thimble eye bolts, eye nuts and eyes

- Pole fittings

- Guy strain insulators

How to install the Guy grip Dead End?

Guy grip Dead End installation is very simple:

- Ensure that your connection extends to the area that has a bend.

- Install the subject conductor along the strands of the guy grip. Ensure that the conductor fits perfectly on the strands of the grip.

- Fit the conductor to the end of the guy grip then cover the strands using the opposite side of the guy grip so that they overlap each other.