Utility Washer

Utility washers are utility pole parts that majorly play a protective role. The main function of a washer is to prevent the corrosion of the steel screws. They can do this by providing the required insulation.

Because of their functions, washers are usually considered to be part of the fasteners, especially on the bolts and nuts. They minimize the strain on the fastener.

We have different variants of washers. These are spring washers, square washers, curved washers, lip washers, centering washers, and lock washers.

Each type of washer is designed for its specific application. For instance, the curved washer is ideal for a wooden pole while the square washer is best suited on a concrete pole.

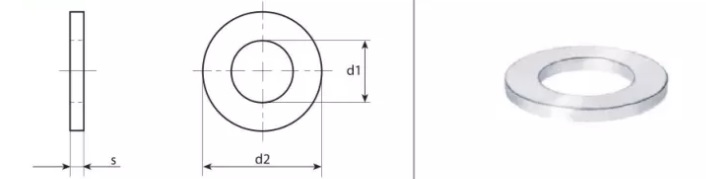

In terms of design, a washer for the overhead power line has a hole in the middle. The diameter of the hole matches that of the bolt.

The sizes or dimensions of these power line fittings vary from one washer to another.

For the material, our washers are made of flat steel which is trimmed into different sizes. They are then hot-dip galvanized for surface protection.

Regardless of the type of power line washer that you are looking for, don’t worry. As a reputable utility washer manufacturer in China, we have all the types.

| Product | Washer |

| Material | Q235, 45#, AISI304(A2-70), AISI316(A4-80) etc |

| Size | 1/2”-4”, M5-M64 or non-standard as request & design |

| Grade | 4.8, 6.8, 8.8, 10.9, 12.9 |

| Surface | Plain, galvanized, blue white, YZP, etc |

| Type | flat washer, star washer, spring washer |

Utility Sheet Metal Washer

A sheet metal washer is a pole line accessory that is used for spreading or distributing the load of a screwed fastening. It provides extra support to the screw and bolt heads.

The metal washer sheet is placed beneath the head of a bolt or screw used in sheet metal work. The sheet metal washer is typically made from sheet brass or steel.

It acts as a support for the sheet metal against which it works in conjunction, bearing the load on its surface, spreading and distributing it over a larger area.

This helps to prevent deformations or buckling of sheet metal and keeps it from being drawn into the sheet metal. These sheet metal washers are also called sheet metal shims, sheet shims, or sheet metal wafers.

The sheet metal washer can also be made in a rolled form with its use orchestrated to that of a conventional “washer” but using sheet metal, not sheet metal.

It is also used for sheet metal bending in order to stabilize the resultant edges of sheet metal during sheet metal work. The washer’s use can be likened to that of a gasket since it must have a close tolerance fit.

The sheet metal washer is often assembled with sheet screws or sheet bolts and sheet metal nuts.

In a pole line, power sheet metal washers are sheet metal washers that are used at joints to sheet metal conduits and pipes running high voltage electricity, or other electrical currents. They are also called sheet metal insulators due to their function in the system.

They are typically made of sheet brass because of their fatigue resistance (i.e.: resistance to deformation under repeated physical strain).

Types of utility metal washers

There are different types of power metal washers. They include:

Round metal washers

Round metal washers are in circular shapes, with a hole on the middle of it. The material for metal washers varies from metal alloy to metal compound. There are also special metal washer engineered for specific purposes and applications.

Round metal washers are quite common in electrical line applications.

Round metal washers are available in metal alloys: aluminum metal alloy, metal iron metal alloy.

Metal washers can also be used as center part of a bolt nut to prevent metal from being exposed if the head of metal is for example damaged. This way the bolt nut can still provide support and fix objects, or parts together.

Square washer

These washers are also quite common in power lines. The metal variation of metal washers is also widely used, for example metal alloys like metal iron metal washers. Square metal washers have long been used in the power and telecommunication sectors. Metal square washers are generally used to fix shafts together with bolts.

Square curved washer

Square curved washers are also common in transmission line installations. They are available in metal alloy and metal compound. Metal square curved washers have a curved line instead of straight lines, which makes it easier to hold and grasp when tightening bolts on metal shafts.

Centering washer

The centering washer metal is used to hold the metal in place and keep metal from vibrating, or slipping on metal shafts. When it comes to the transmission lines, this type of washer metal is used to hold metal bolts and nuts together, and keep metal from slipping.

Lock washer:

A metal lock metal washer is used to keep metal parts from moving, or falling out of place. First metal lock metal washers are also used for fastening metal objects together.

This type of metal washer can be metal galvanized, which means that they have a metal zinc coating on top. Zinc is one of the key metal components that make metal lock metal washers stronger and more robust.

Ring metal washer:

This is another type of washer that is used on pole lines.

When it comes to metal ring metal washers, their shape is like that of a cup, or a dome. They are also very useful in preventing metal bolts from vibrating out of place when they are being tightened.

Conclusion

In conclusion, it is clear that utility washers or metal washers are of great importance on pole lines or transmission lines. The metal washers for example play a very important role on transmission lines.

Utility metal washers are used in conjunction with metal bolts to prevent vibrating and loosening of metal lock bolts. So, choose the right utility washers for your applications.