The drop wire clamp is used for supporting one or two pairs of fibre drop wires. With an open trough, it is used to support strands that are separable. A shim, shell, and wedge are used to support the cable with the help of compression.

Table of Contents

What is Drop Wire Clamp?

A drop wire clamp enables a cable, like a coaxial cable, to get attached and supported to a pole, building, or any other kind of support wire in a way that decreases any compromise be made to the signal transmission capacity of the drop wire cable. The clamp is also beneficial as it supports the cable weight and sets the tension on the line as it relieves the stress on the points of attachments, such as the juncture through a building or a pole.

A drop wire clamp is utilized to augment a single and two paired fibre drop wire at drive hooks, span clamps, house hooks, and various other attachments for the drop. In addition, drop wire clamps are utilized to support the aerial service terminals drop span at the messenger and building strand. In most cases, these clamps are removable.

The drop wire clamps are useful as the double-stranded figure comes with a plate (aperture) as well as a trough that gets lowered from the end of the trough fast. This makes the clamp suspended from the appropriate anchor. The trough is sized well to accept the cable with no requirement of threading. Furthermore, there is no need for compression on the part of the cable which carries the signal. This cable is set in the trough by wrapping the isolated support strand that surrounds the trough.

Types of Drop Wire Clamps

Drop wire clamps consist of two types:

- Wire wrap type

- Compression type

Both of the types require that the clamp does not get degraded by the signal quality through damaging the signal being carried in the cable or the insulation.

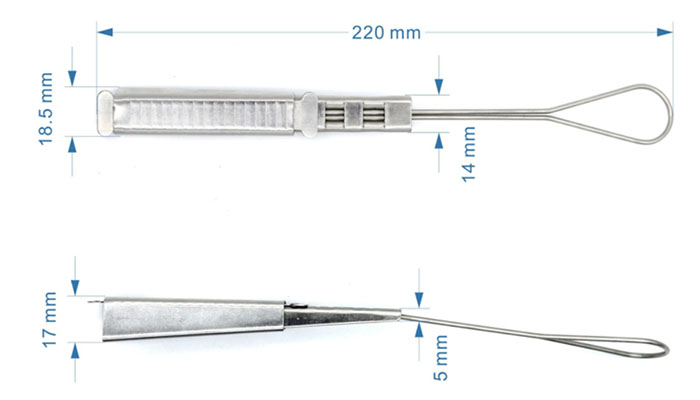

The Design of the Drop Wire Clamp

The drop wire clamp is made of an open trough that can take in a cable without threads, whereas, the open portion of the trough is defined well through edges and is supported in order to become able to support the strands which get separated from the drop wire clamp. On the other hand, the plate is extended from one end of a trough and provides sources for engagement.

Features of the Drop Wire Clamp

- It can carry a maximum load of 500 to 700 pounds

- It is made of stainless steel with three pieces of construction

- Supports one and two pair of the telephone drop wire

- Removable

How to install a Drop Wire Clamp?

First of all, lay the cable in the shell and place the shim on the top of the cable through raised embossing used against the cable. You need to then insert the wedge in the shell which is on the top of the shim and then pull to engage. The small end of the wedges needs to be engaged in the track of the large end of the shell. You can then place the bail wire on the B drop wire hook through the help of a wedge loose. Then, pull the drop wire through the clamp until the proper side walk or the alley clearance is attained. Then, you need to grasp the clamp and pull it tightly for securing it.

The drop wire clamp with its intelligent structure and form is used to provide support to different objects at a cable. In most cases, it is capable of supporting one and two pairs of telephone drop wires.

Drop Wire Clamp Manufacturer

Powertelcom is a leading supplier of drop wire clamps and a premier manufacturer of power line hardware and fittings in China. We supply an extensive range of electrical hardware components to over 11 market segments, including the telecommunications and electronics sectors, as well as the automotive and aviation sectors.

We can also make products to your specifications. Many of our metal components can be found in a variety metals, including aluminum, steel and platinum.